Minimizing Risk: Strategies for Design and Construction

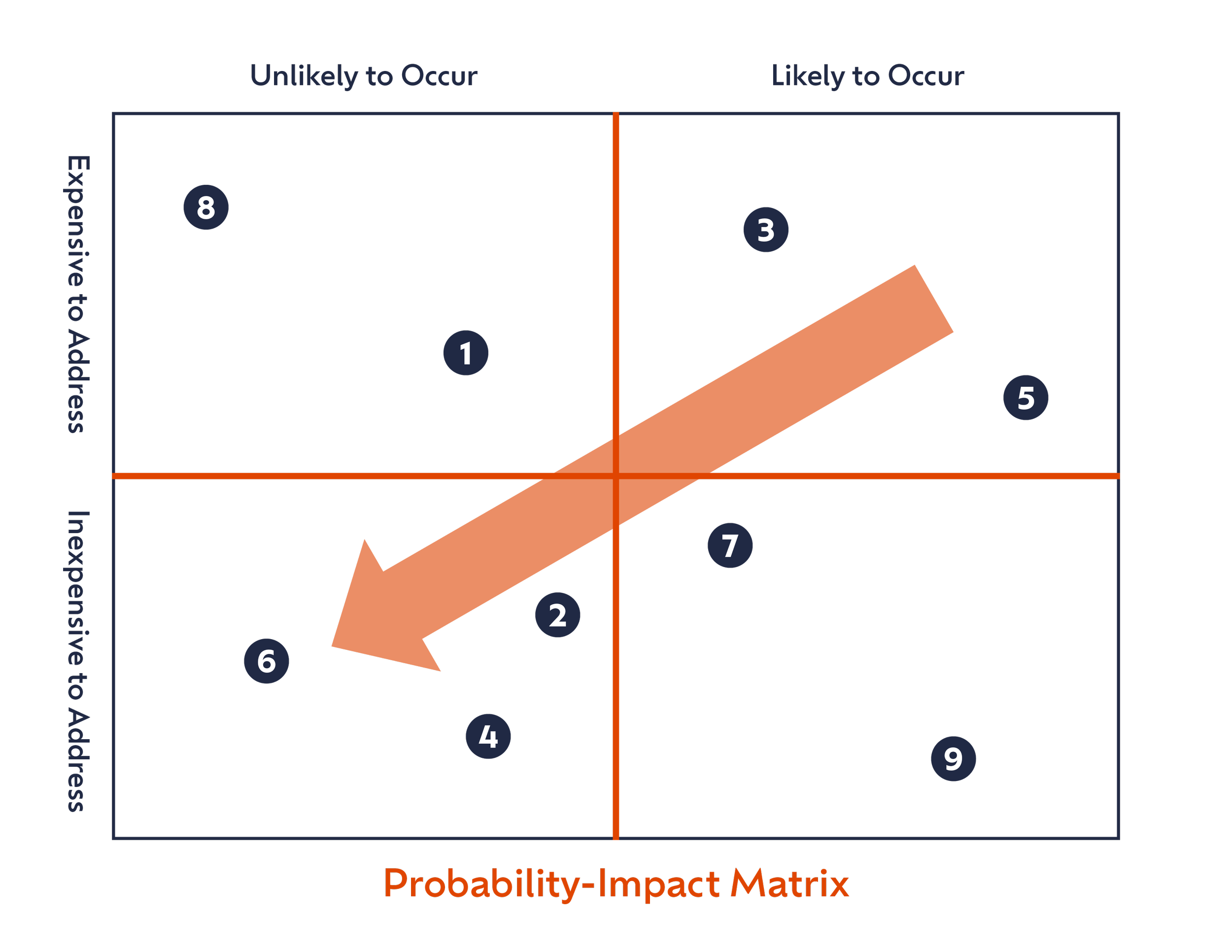

Probability-Impact Matrix. Image: © Precis Engineering + Architecture

Modern laboratory design supports innovation, regulatory compliance, and resilient, high-performing workspaces. Decisions directly affect productivity, legal exposure, and the health, safety, and welfare of users. From the start of any design and construction assignment, project stakeholders invite opportunities for risk.

But with practical strategies and tools to identify, mitigate, and manage risk, a team of architects, engineers, lab planners, facility managers, and end-users can work together—transparently and proactively—to establish a culture that removes most risk before it ever takes shape.

What is risk?

Risk can be defined as anything that causes damage, loss, or harm. According to an oft-cited Construction Industry Institute (CII) study, most construction projects include about 57 percent waste1. Statistics across construction and tech industries find that between 67 and 91 percent of projects are over budget, late, or both2. Cost and budget overruns are the visible results of unmitigated risk; causes often include poor project definition, documentation errors, supply chain delays, health and safety hazards, change orders, and cost disputes.

How does flow impact risk?

Flow represents the rhythm and connectivity of a project team. It describes how well people communicate, understand expectations, and respond to change. Flow isn’t static—it evolves with the project and can be classified into three key categories: reactive, active, and proactive. Reactive flow responds to risks after they arise. Active flow responds to risks as they take shape, often with structured tools and collaboration. Both, however, are reactive problem-management approaches, as the issue itself already exists. In contrast, Proactive flow identifies risks before they emerge and offers the best opportunity to absorb or remove risk factors. True risk management operates with proactive flow. This approach reduces disruption and optimizes performance by empowering teams to operate with clarity and intention, rather than fear or anxiety. When a team feels aligned, trusted, and prepared, they take bold steps with confidence.

Kevin Hollenbeck and his colleague Amanda Jones will lead the interactive workshop “Minimizing Risk: Liability-Aware Lab Design Strategies” at the 2026 Lab Design Conference in Orlando, FL, on May 11. Spots are limited, so register now to secure your place—please note, workshops are an add-on to your conference ticket.

Typical design and construction delivery approaches handle risk inefficiently, often in a reactive, rather than proactive manner. Teams may adopt an ignore-and-avoid approach or a wait-and-see mentality; either way, crises are met with stress, indecision, and delays as issues are addressed. The most successful project teams integrate risk thinking into the foundation of early-stage design and then incorporate cultural and technical tools throughout the process. Within this framework, risk transforms from a threat into a driver of clarity, alignment, and positive outcomes.

Strategy 1: Visioning the “why”

The most successful project teams integrate risk thinking into the foundation of early-stage design. A visioning session for all project stakeholders provides a great opportunity to spur dialogue, build trust, and clarify which values should guide key decisions. Begin by asking each person, “What do YOU feel will make this project a success?” Each answer is then evaluated and discussed as a group. Answers may range from schedule and budget to aesthetics, flexibility, or ability to grow in place. Overlap and prioritize the goals for transparency and shared understanding. When all parties begin with shared intent, communication improves, trust builds, and decisions are made with purpose. Transparency around goals, tradeoffs, and constraints creates a stronger partnership between owner, designer, builder, and other teammates.

Strategy 2: Probability-impact matrix

Early in the process, engage all stakeholders in similar dialogue to identify potential challenges. A probability-impact matrix is a four-quadrant graph on which teams identify situations more or less likely to occur and with higher and lower cost impacts. This visually articulates priority based on probability or potential impact. More importantly, it illustrates which should be actively managed vs. which can be removed entirely through early decisions and design strategies. The matrix can be paired with a documented project crisis threshold, the level of acceptable risk at any given time, wherein the project will still recover without significant impact to cost, schedule, or trust.

Strategy 3: Compounded planning

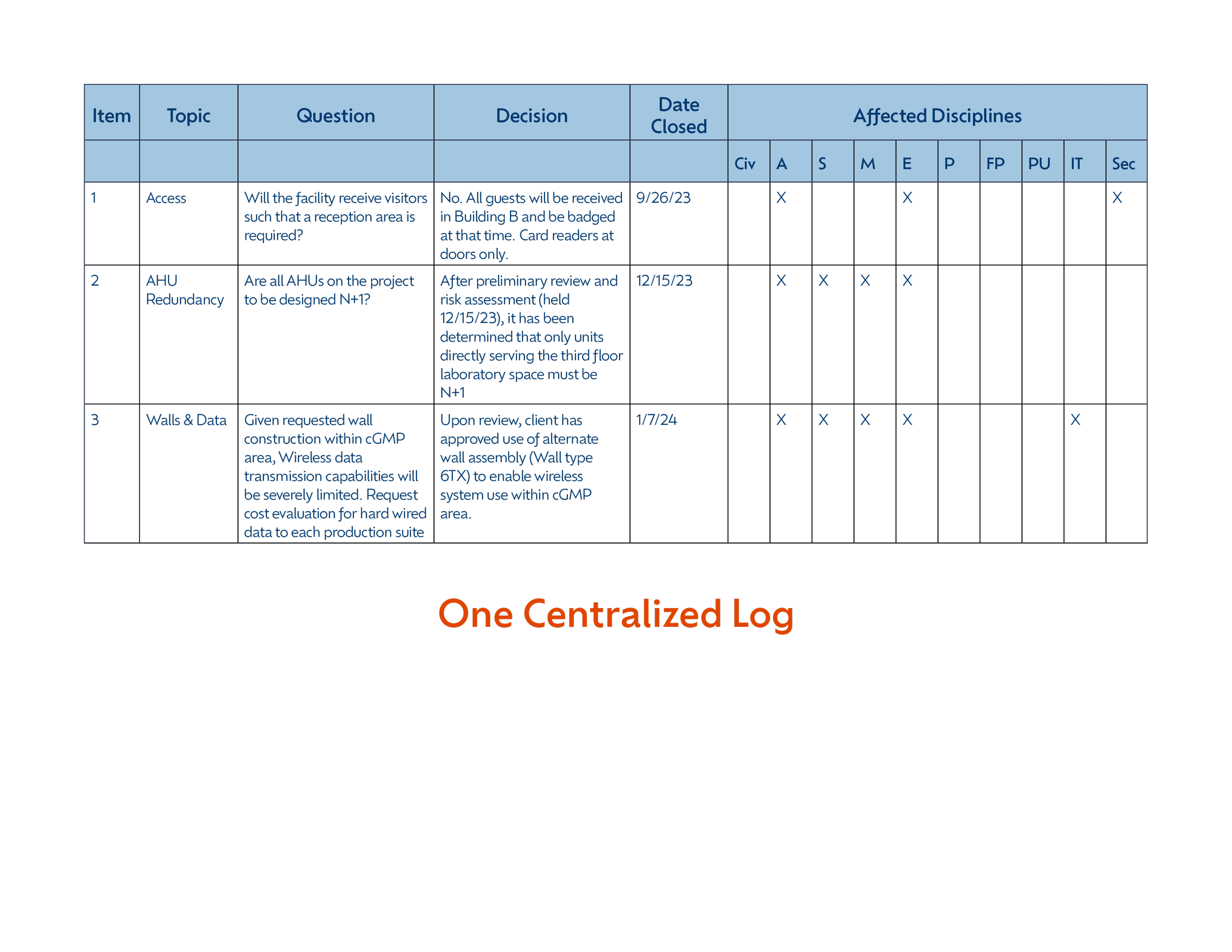

One Centralized Log. Image © Precis Engineering + Architecture)

Risk management evolves along with a project. A compounded work plan provides a framework that accelerates decisions. In a compounded work plan, each phase of work feeds the next, providing increased detail that improves efficiency and speed. In a traditional design process, concept development is followed by the basis of design, design development, and construction documentation. Each subsequent phase takes longer as the design undergoes refinement.

If by instead reversing the approach and spending more time on the earlier phases, the longer investment in concept development can flag potential roadblocks that may occur later. Meetings play an important role in this approach; every meeting has a clear intent, primary questions to be answered, and topics to be addressed, all of which directly feed the next decision, meeting, and process. Formal sign-off at key delivery stages can be included in compounded planning. Not simply a notice-to-proceed but a formal agreement of scope acceptance and approval based on that scope fosters engagement between client and designer.

Compounded planning begins with understanding, followed by refinement, development, then documentation. It creates a feedback loop that helps the team grow and improve. The system of continuous learning is not unlike scientific experimentation—each process benefits from what has already been learned.

Strategy 4: One centralized log

Too many tracking tools can cloud communication. Centralizing decisions in a single, living document ensures continuity and reduces risk through subject revisitation. A shared decision log gives every teammate visibility into why choices were made, and which disciplines are affected. It also allows for informed decisions if conditions change.

Strategy 5: Proactive code approaches

Proactively approaching code compliance can both minimize risk and lead to improved building resiliency. In a recent project where space was at a premium, the team identified early in design a need to incorporate a firewall between an existing facility and the new, connected building. In conventional design, a firewall is composed of two rated walls built next to each other, each connected to a different structural system and serving as a shield for the facility in case of fire; the rationale being that if one burns and collapses, the other wall remains standing to protect the other area from damage. In most cases, the building structure is rated lower than the wall, as the wall is designed to protect the facility. And to maintain integrity to the wall design, any penetration through the firewall requires a bubble vestibule to allow a user to pass through both portions of the firewall. This final requirement became an insurmountable mathematical challenge to the design due to finite limitations of the site and buildable square footage.

After re-reading the code and discussing not only the how but also the intent of the code, the design team proposed creation of a single firewall design wherein the supporting structure received an increased fire rating to match the wall. This strategy would effectively ensure the wall would satisfy the building code’s intent regardless of which side of the wall a fire might occur.

Rather than deferring this discussion to the documentation or permitting stages of the project, the team engaged the local fire code official during the concept phase to review the hardship and seek input regarding potential solutions. After reviewing the concept, the official agreed that not only did the design meet code intent, but it also created a safer condition for occupants and firefighters in the event of a fire by ensuring the structure would remain standing longer than code required.

As an additional note, the design team encountered a similar situation in another state and successfully gained approval to implement this approach there as well. The example proves that early discussion and a proactive approach can mitigate risk and ultimately lead to a better building.

Strategy 6: 3D visualization

Design professionals can leverage building information modeling (BIM) software to integrate design documentation across disciplines, perform real-time clash detection between systems, and address issues during design rather than during construction. While BIM supports design and construction team integration, it may not be as helpful to owners or end-users. Many clients—especially in the pharmaceutical sector—are not trained to read technical drawings. They may sign off on a layout, only to realize during construction that a space does not meet expectations. Architectural modeling programs—such as Enscape™ and Lumion—provide advanced visualization to avoid this risk. With 3D models and virtual reality, end-users can experience spaces and provide feedback before a single wall is built. These tools bridge communication gaps, align stakeholders, and help clients make confident, informed decisions. This approach reduces surprises, improves satisfaction, and ultimately delivers a better outcome.

Strategy 7: Modularity and prefabrication

Modularity can make the simple appear complex and make the complex elegant by introducing new levels of control, predictability, and time savings. Using prefabricated materials and modular components accelerates construction schedules, supports sustainability goals by reducing waste, provides less disruption for urban or high-density sites, and offers enhanced levels of quality control.

Owners and architects may already be aware of modular interior and exterior wall panels, unitized exterior glazing systems, and prefabricated solutions such as stairs and racks. Engineering options include prefabricated process skids that contain all of the piping, tanks, and related equipment for processes within or atop a steel frame, or pre-engineered mechanical, electrical, and plumbing systems with integrated utilities such as compressed air, hydronic pumping, or chilled water. These solutions offer high levels of customization while saving time in the field.

Other considerations include access panels incorporated into building envelopes to accommodate installation of large equipment such as MRI machines or electron microscopes. During design, the team should consider the lifespan of large items that must be craned into a building and incorporate options for removal and replacement. A seamed opening on the building exterior can be removed and replaced with little impact to building structure or visual aesthetic.

Overhead utility panels (OUPs) present another opportunity for modularity. Typical OUPs are made by die-cutting space for a specific number of outlets and valves required by each panel. One lab panel might require three outlets and three lab gases; another might require eight outlets and two gases. Each custom die-cut incurs a cost and time impact. If by instead identifying the maximum number of potential spaces required in any given lab, the OUPs can be fabricated with a standard number of spaces. Unused spaces can be covered when not required. This not only saves time and expense during construction but also provides adaptability, cost savings, and schedule reductions to future projects as lab functions change over time.

Don’t miss the hands-on workshop “Minimizing Risk: Liability-Aware Lab Design Strategies,” led by Kevin Hollenbeck and Amanda Jones on May 11, kicking off the 2026 Lab Design Conference in Orlando, FL (May 11–14). Space is limited for this interactive session, so be sure to reserve your spot!

Culture as a catalyst

When culture supports curiosity, alignment, and ownership, it becomes a catalyst for successful project outcomes. Teams that frame their projects clearly and remove ambiguity also create opportunity for innovation. But this positive flow cannot evolve unless it begins early.

By redefining risk and embedding risk management principles into planning, teams shift from reactive to proactive. When this culture of collaboration and shared values extends to the thoughtful use of tools and technology, the idea of risk management becomes less about solving crises and more about enabling success.

References

Richard Hannis Ansah, Shahryar Sorooshian, and Shariman Bin Mustafa “Lean Construction: An Effective Approach For Project Management.” Vol. 11, No. 3, February 2016 ISSN 1819-6608 ARPN. Journal of Engineering and Applied Sciences.

Daniel Akst. “Why do large projects go over budget.” June 19, 2023. Strategy + Business, a pwc Publication. Accessed 29 September 2025, https://www.strategy-business.com/article/Why-do-large-projects-go-over-budget