Upgrading Viral Clearance Labs for Capacity, Collaboration, and Comfort

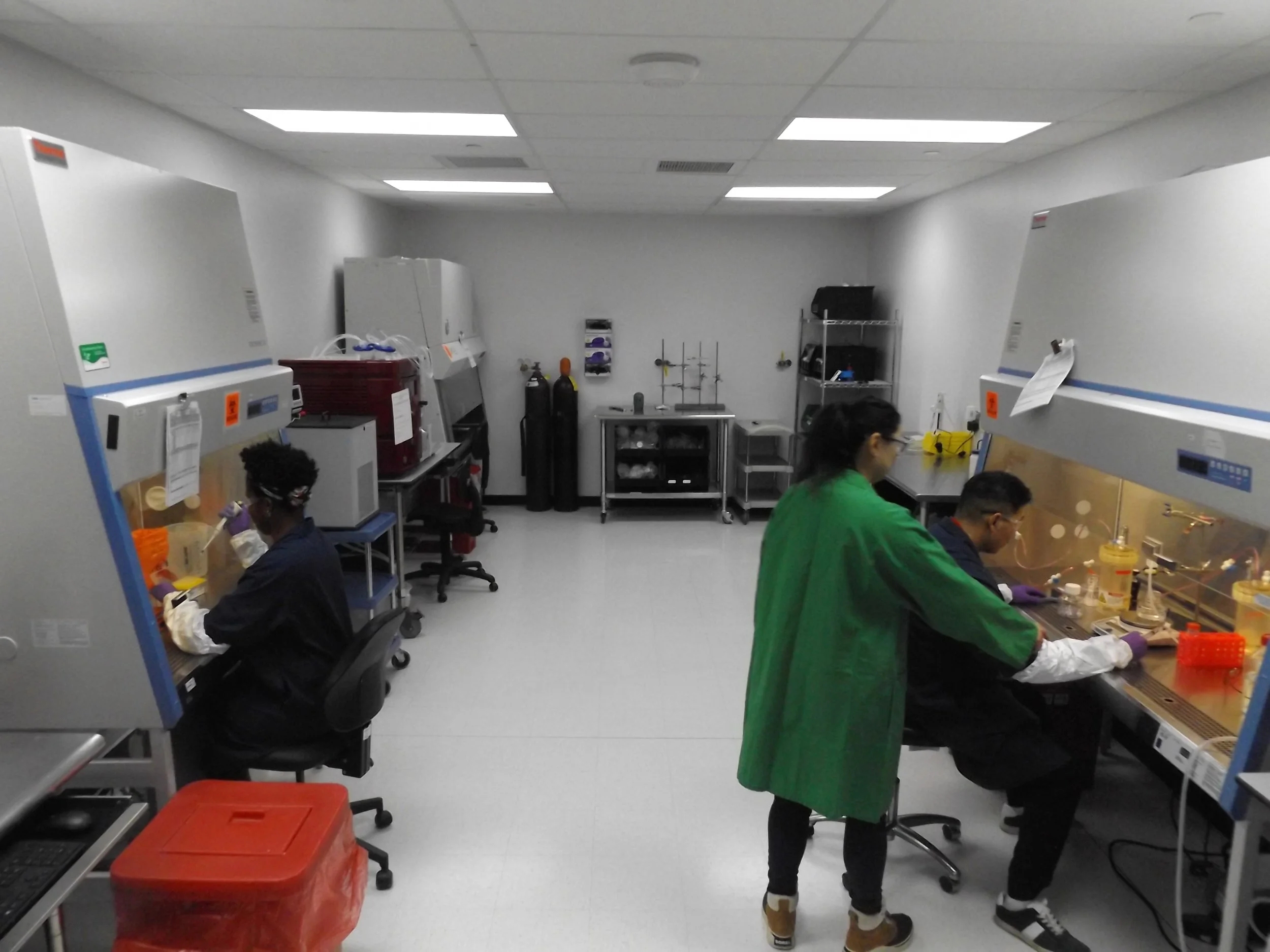

Minaris’ upgraded viral clearance laboratory in Philadelphia demonstrates how strategic design can enhance biosafety, regulatory compliance, workflow efficiency, and client experience—all without adding square footage. Image: Courtesy of Minaris

Upgrading a viral clearance laboratory is rarely just a matter of adding square footage. These environments must balance biosafety, regulatory rigor, throughput, and an increasingly important factor: the experience of visiting sponsors who may spend long days working alongside scientists.

At Minaris’ Philadelphia campus, a recent viral clearance laboratory upgrade demonstrates how thoughtful design and infrastructure investments can expand capacity while simultaneously improving workflow, transparency, and comfort for both staff and clients.

The primary driver behind the project was straightforward but ambitious. “The primary design driver to upgrading viral clearance laboratories was to expand the space and capacity of our operations,” the Minaris team (comprising Johnna Tansimore, supervisor—viral clearance; Kathleen Kenney, director—viral clearance; Tim Burns, manager—viral clearance; and Andreas Solomos, director—virology operations) tells Lab Design News.

Just as important, however, was the desire to support more on-site client engagement. “The upgrades were designed to enhance our ability to host on-site clients while also strengthening infrastructure and power capacity,” they note—priorities that would ultimately shape everything from layout and access control to furniture selection and digital integration.

A layout built around segregation and flow

At the heart of the upgrade is a new facility layout anchored by four dedicated, state-of-the-art client suites. Each suite is paired with private conference rooms and designed to provide clear separation between laboratory operations and client-facing activities. According to the Minaris team, “The new facility layout includes dedicated client suites and private client conference rooms, providing clear separation between client activities and laboratory operations.”

This separation is reinforced through controlled access. “The clients have badge-controlled access within the building, permitting independence and confidentiality,” they add. This approach underscores a key takeaway: physical segregation does not have to come at the expense of collaboration. Instead, it can create an environment where multiple studies can operate concurrently without congestion or compromise.

Flexibility inside the client suites

Within each client suite, flexibility was a guiding principle. Viral clearance studies vary widely in scope and configuration, and the upgraded spaces were designed to adapt quickly. “Each suite was designed for a more open and flexible layout to support concurrent studies and client presence,” the team explains.

One of the most impactful changes was deceptively simple. “The benchtops were converted to rolling tables, making it easy to adapt the space for different types of studies or client needs.” This move away from fixed casework allows the lab to be reconfigured efficiently, reducing downtime between studies and supporting a broader range of protocols. For end users, it also means fewer workarounds and less reliance on hallways or adjacent spaces for overflow.

Digital visibility without compromising compliance

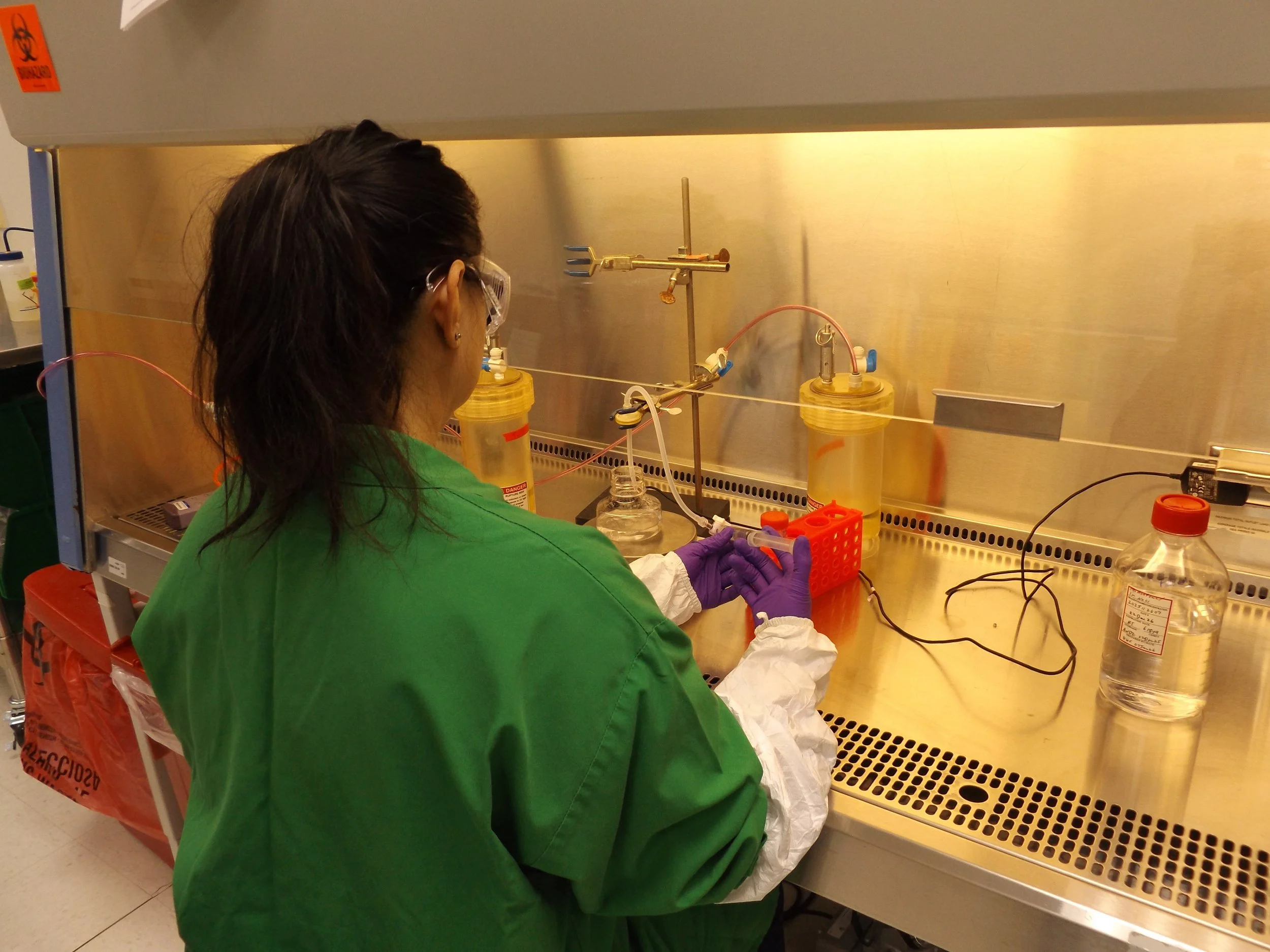

The redesigned viral clearance lab eliminates overcrowding, improves workflow and visibility, and enhances client comfort with open sightlines, upgraded furnishings, and thoughtfully integrated technology. Image: Courtesy of Minaris

Integrating advanced digital tools into a regulated biosafety environment requires careful coordination between IT, quality, and facilities teams. In this case, remote monitoring capabilities were layered into the physical environment without disrupting core compliance requirements. “Viral clearance is GLP-compliant but also adheres to applicable GMP requirements,” the team emphasizes. “We can provide remote monitoring through secure IT systems, giving clients visibility into study activities without disrupting laboratory operations.”

This digital visibility is particularly valuable for Validation on Demand (VOD) services, where sponsors actively participate in studies. “By securing remote access to our AKTAs via the Unicorn Software, the clients can view their VOD study in real time in the comfort of their private conference room,” they say. The result is closer collaboration without unnecessary traffic in controlled lab spaces.

Improving daily workflow and occupant experience

For scientists and technicians, the most immediate improvement has been the elimination of overcrowding. “The redesigned space has improved daily workflows by eliminating overcrowding, making the labs easier to navigate,” the team shares. “Scientists in the lab spaces benefit from enhanced layouts as there is no more overcrowding, no more using the hallway for overflow storage.”

Clients benefit from this clarity as well. With improved sightlines and a more open concept, “our clients gain better visibility into lab operations,” reinforcing trust and transparency throughout the study lifecycle.

Occupant comfort was also addressed directly, particularly in spaces where clients may spend long hours reviewing data or meeting with scientists. “Visibility and ease of use were important considerations to the lab improvements, and they have made the lab feel more accessible and transparent with the open concept,” the team notes. New furniture (including couches and personal desk space) and technology have been outfitted in the client conference rooms, supporting ergonomics and comfort without undermining professionalism.

Infrastructure as a throughput multiplier

Behind-the-scenes infrastructure upgrades—including enhanced HVAC, electrical reliability, and emergency power—boosted throughput by 25 percent while phased planning and flexible execution kept the viral clearance lab fully operational during construction. Image: Courtesy of Minaris

While layout and furnishings played an important role, the most significant gains in throughput—approximately 25 percent—came from behind-the-scenes upgrades. “The increase in throughput is credited to improved infrastructure dependability like upgrading the air handlers and the electrical systems,” the team explains. Ensuring that critical equipment is protected by emergency power and that HVAC systems perform reliably has enabled the lab to “run multiple studies at the same time empowering advanced productivity.”

This reinforces a familiar but sometimes overlooked lesson: infrastructure investments often deliver the highest return in terms of operational efficiency.

Executing the upgrade while maintaining ongoing operations required careful coordination. “The biggest challenge was coordinating with multiple vendors while managing material availability and lead-time constraints,” the team says. Phased execution, clear communication, and detailed planning allowed laboratory activities to continue safely throughout construction.

Looking back, flexibility emerged as the most important lesson. “One key lesson learned from this project is the importance of patience and building flexibility into both the project planning and execution in addition to the physical space you are designing,” they reflect. Sharing responsibilities and planning for backup resources helped reduce risk and keep the project moving forward, even when challenges arose.