Modernizing a Mid-Century Lab for 21st Century Research

While functional, the lobby lacked adequate light and felt darker than it should. Image: Courtesy of Cooper Carry

As research institutions across the country wrestle with the challenge of aging infrastructure, the University of Georgia’s renovation of its 1960s-era Chemistry Building—now Cedar Street Building C—offers a powerful model for what’s possible. Cooper Carry’s Science + Technology Studio led the architecture, programming and predesign, and interior design, alongside of contractor Holder Construction and MEP/FP firm Newcomb & Boyd.

Lab Design News interviewed Cooper Carry’s principal Mark Jensen and associate principal Markus Wilms to discuss how this project showcases the ability of design teams to convert aging legacy buildings into cutting-edge research facilities—successfully balancing historic preservation, adaptability, and sustainability.

Balancing historic preservation with modern performance

From the outset, the Cooper Carry team prioritized honoring the building’s original design while upgrading it to meet the demands of a 21st-century research facility. “Preserving the structure was ultimately more valuable than starting from scratch,” say Jensen and Wilms. “There was the saving in cost aspect versus investing $35M to $45M on a completely new building, as we also wanted to honor the campus’ history.”

This commitment to preservation meant working within an 11-foot floor-to-floor height—well below the 15-foot heights standard in new lab buildings. That constraint shaped one of the project’s most complex technical challenges: how to integrate modern mechanical, electrical, and plumbing (MEP) systems without compromising ceiling heights or functionality.

The solution required an “integrated design process that carefully balanced engineering, architecture and construction issues,” say Jensen and Wilms. A new central mechanical room was constructed to house air handling systems, and a centralized exhaust system replaced decades’ worth of patchwork rooftop installations. Creative routing strategies—such as threading ductwork between concrete beams and reusing vertical shafts—allowed the team to maximize ceiling heights in labs and offices.

Flexibility by design: supporting multidisciplinary research

A view of the MEP systems. Image: Courtesy of Cooper Carry

Cedar Street Building C now houses the College of Agricultural and Environmental Sciences’ entomology departments and the Franklin College of Arts and Sciences’ microbiology and cellular biology departments. Designing for multiple disciplines within a single building posed challenges—but also opportunities.

The team’s solution: flexible open labs paired with specialized support spaces, such as secure insect containment labs and walk-in environmental chambers. “A core mission of the project was to create flexible lab spaces both for the open collaborative research labs and the support labs,” say Jensen and Wilms. “This allowed changes and adaptations during the later design phases and in the ongoing use of the building as programs and end users changed and will change in the future.”

That adaptability was especially valuable when stakeholder feedback resulted in real-time design modifications. For example, a previously underutilized staircase was eliminated, creating 3,000 sf of “commons” space in the center of the building. Now dubbed “the Crossroads,” the collaboration zone is outfitted with natural light, A/V, whiteboards, and comfortable seating—and is frequently used by students and faculty alike.

Sustainable strategies that make the most of what’s already there

Rather than demolish the aging structure, UGA and Cooper Carry opted to reuse 77 percent of the original building shell and enclosure. An embodied carbon analysis found that this decision conserved emissions equivalent to removing over 1,000 cars from the road annually. “This renovation effort demonstrates the viability of reuse for modern-day research buildings,” say Jensen and Wilms.

The team supplemented the reused structure with a host of sustainable upgrades:

Chilled beam HVAC systems, which use water rather than air to deliver heating and cooling, reduce duct sizes and energy consumption.

Energy recovery from exhaust air helps precondition incoming air.

LED lighting with occupancy and daylight sensors minimizes energy waste.

Spray foam insulation and window replacements improve envelope performance.

Concrete flooring replaces vinyl tile, offering a lower-maintenance, more durable finish appropriate for BSL-2 research environments.

These measures are expected to reduce annual energy use by at least 10 percent compared to a typical new lab building, making the project not just cost-effective, but environmentally responsible.

Preserving character without compromising usability

Lab tools are arranged in a colorful display, delivering functionality and aesthetic form. Image: Courtesy of KBPhoto

A defining aspect of the renovation was maintaining the mid-century character of the original building while upgrading its performance. “The project’s new interior finishes were selected to honor the building’s mid-century history,” say Jensen and Wilms. “Custom concrete breeze block interior screen walls, polished concrete floors, wood finishes and exposed structural elements reflect the building’s original character.”

At the same time, critical building systems and envelope components—roofing, windows, brick veneer, flashing, crawlspaces—were repaired or replaced to modern standards, ensuring durability and comfort for decades to come. The building’s once-failing crawlspace was fully encapsulated and conditioned to improve indoor air quality and thermal performance.

Lessons for future renovations and vendors

Lab facilities include open laboratories, microscopy rooms, insect containment facilities, walk-in environmental chambers and plant growth spaces. This photo showcases one of the open labs. Image: Courtesy of KBPhoto

As Phase II of the Science Hill transformation—focused on the Biology Building—moves forward, the Cooper Carry team is already applying lessons from Cedar Street Building C. “The first renovation demonstrates the viability of reuse as modern-day research buildings,” say Jensen and Wilms. “We are hopeful that this continued demonstration of revitalization of existing space, which is more cost-effective than building new, will lead to sustained funding support for further phases.”

For other designers and institutions undertaking similar renovations, key takeaways include:

Conduct thorough due diligence on structural infill conditions early in the design and preconstruction phases.

Coordinate early with lab equipment providers to ensure infrastructure compatibility.

Polished concrete can be a viable and durable flooring solution in BSL-2 environments.

Use underutilized vertical space (such as structural beam pockets and vertical shafts) for creative MEP routing.

Identify and eliminate unnecessary elements (like stairwells) that can be repurposed for collaborative use.

And for lab equipment vendors and MEP partners: participating early in the design process can help shape more efficient infrastructure solutions that work within legacy building limitations.

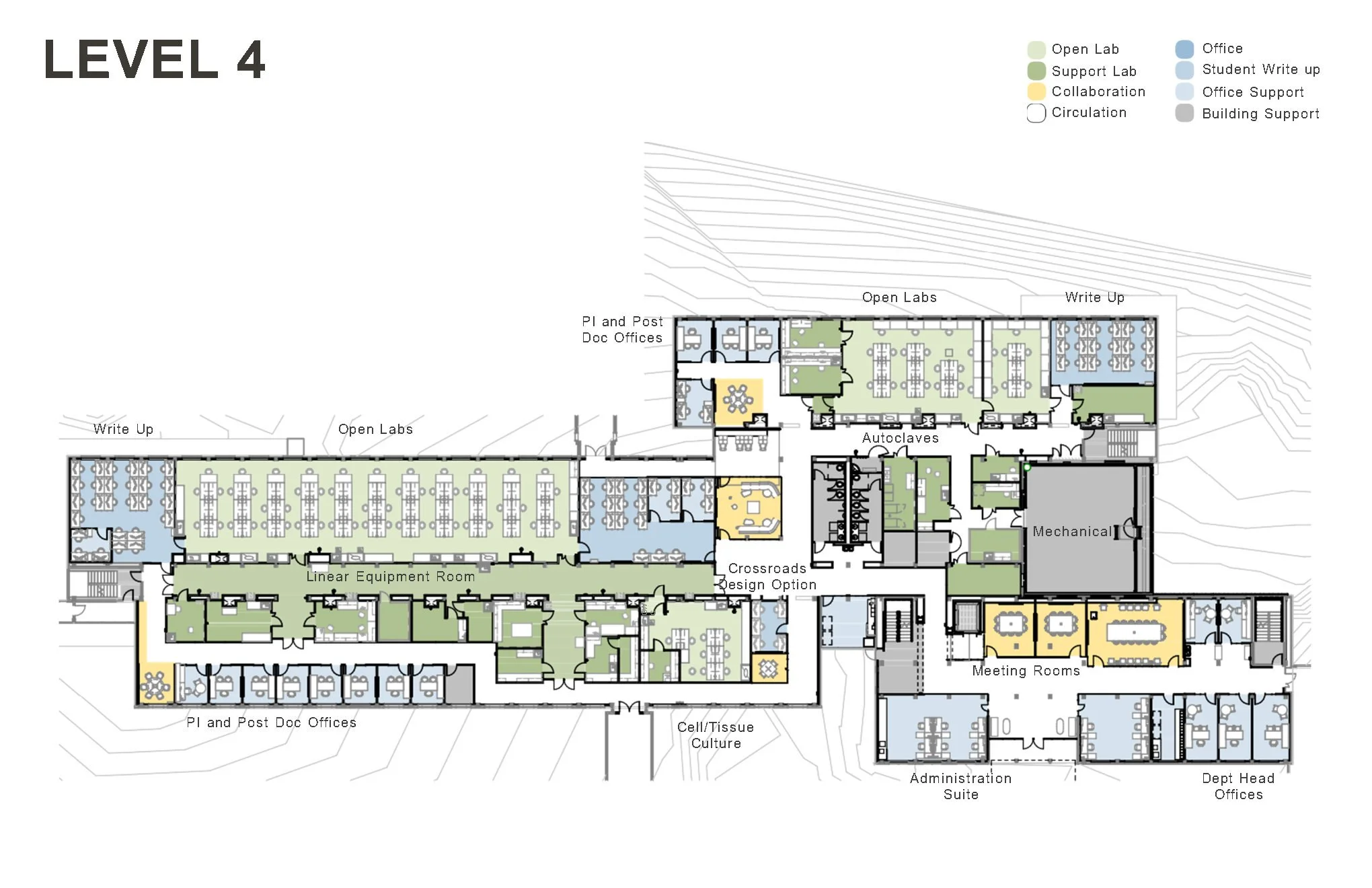

Floor plan courtesy of Cooper Carry

Looking ahead

The Cedar Street Building C renovation is more than a successful lab upgrade—it’s a compelling argument for reuse over replacement, for collaboration over compartmentalization, and for sustainability embedded in every design decision. As Jensen and Wilms put it, “We were committed to determining the most effective ways to improve functionality, while making the best use of the existing structural features.”

The success of Phase I, supported by strategic partnerships and strong stakeholder engagement, is already influencing future phases of Science Hill’s modernization—setting a standard for campuses across the country grappling with aging lab infrastructure.