Inside Southern Miss’s State-of-the-Art Oyster Hatchery

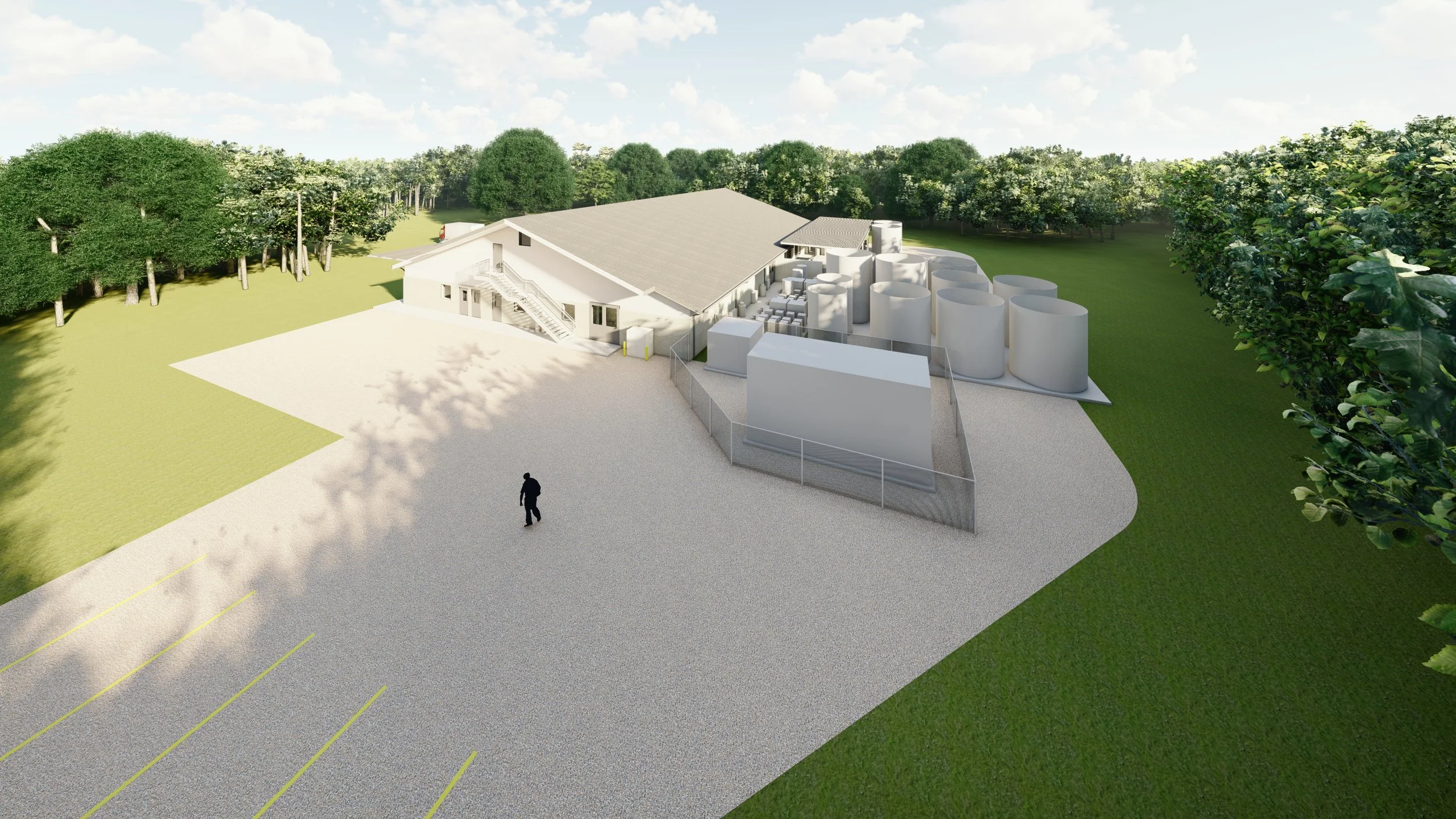

Construction is underway on The University of Southern Mississippi’s new oyster hatchery at the Thad Cochran Marine Aquaculture Center in Ocean Springs, a state-of-the-art facility designed to produce up to one billion larvae per year and support oyster restoration along the Gulf Coast. Image: Courtesy of The University of Southern Mississippi

Construction is underway on a landmark facility at The University of Southern Mississippi (USM) that promises to reshape oyster restoration and aquaculture along the Gulf Coast. Rising at the Thad Cochran Marine Aquaculture Center (TCMAC) Cedar Point campus in Ocean Springs, the new oyster hatchery will be capable of producing up to one billion eyed larvae per year. Expected to be completed in late summer or early fall 2026, the project represents a major investment in the state’s Blue Economy and a vital step toward reversing the steep decline of Mississippi’s oyster populations.

Once a thriving fishery, Mississippi’s oyster harvests collapsed from 500,000 sacks in 2004 to zero by 2019. Overharvesting, disease, extreme weather, and the Deepwater Horizon oil spill—compounded by prolonged openings of the Bonnet Carré Spillway—left public reefs barren. In 2015, then-Governor Phil Bryant established the Governor’s Oyster Council on Restoration and Resiliency to chart a sustainable path forward. The new hatchery is the most ambitious outcome of that initiative to date.

A facility rooted in collaboration

According to Dr. Reginald Blaylock, TCMAC director, and Megan Gima, TCMAC oyster hatchery manager, end user input was foundational to the project’s design. “Hatchery design was guided by the Governor’s Oyster Council objectives and the management goals of the Mississippi Department of Marine Resources. Throughout the planning and design process, TCMAC’s oyster and algae program managers were actively involved in ensuring the facility’s capabilities aligned both with public restoration and management goals and the research needs of the industry,” they tell Lab Design News.

The hatchery’s dual purpose—supporting both restoration and aquaculture—is reflected throughout the design. “The facility is designed to serve both restoration and commercial aquaculture by addressing the shared challenge of larval shortages,” say Blaylock and Gima. “Although the two sectors have different approaches for growing oysters, the larvae required are the result of a common process. The hatchery focuses on addressing the bottlenecks that constrain the production of oyster larvae and seeks to advance the sector through selective breeding to improve broodstock, applied research, demonstration of innovative practices, and workforce development to support other hatcheries and nurseries in scaling their own production.”

Engineering a controlled ecosystem

The new hatchery features a fully recirculating aquaculture system that uses artificial seawater and a biosecure microalgae production setup to create a stable, controlled environment for consistent, high-quality oyster cultivation. Image: Courtesy of The University of Southern Mississippi

Unlike traditional hatcheries that depend on natural seawater, this facility will operate as a fully recirculating, closed system isolated from environmental variability. “This hatchery incorporates several innovative design features,” say Blaylock and Gima. “It includes a production-scale biosecure microalgae system that will provide a reliable and high-quality food supply to the hatchery. Additionally, the oyster production system is a fully integrated recirculating aquaculture system with large water storage capacity. Both algae and oyster production systems utilize artificial seawater, a unique approach that creates a stable, controlled environment for production that reduces the variability in water quality often encountered with natural seawater.”

To sustain this precision-controlled ecosystem, the facility required intensive engineering coordination. “The scale and system integration required for routinely producing over one billion pediveliger oyster larvae per season required significant planning and engineering for mechanical, plumbing, and monitoring systems,” Blaylock and Gima say. “The design includes capacity for approximately 90,000 gallons of water storage and treatment that entails robust mechanical and biological filtration, UV sterilization, and pumping/piping systems. A comprehensive monitoring system tracks water levels and water quality parameters in real time. Hundreds of feet of plumbing were engineered to provide reliability, redundancy, and efficiency.”

From prototype to production

The hatchery’s design is based on six years of research and testing in a quarter-scale prototype, where USM scientists refined recirculating aquaculture systems and developed the methods now used in the full-scale facility. Image: Courtesy of The University of Southern Mississippi

The design is rooted in nearly a decade of hands-on experimentation. “The design of this hatchery is unique. It was inspired by our own operational prototype,” say Blaylock and Gima. “For six years, we have run a one-quarter scale facility in which we conducted research to refine recirculating aquaculture systems using artificial seawater. Our experience has allowed us to develop and refine the efficient and consistent practices for producing both microalgae and oyster larvae that now form the foundation for this new, full-scale hatchery.”

Funding for the $14 million project was secured through a combination of state and federal sources, including the RESTORE Act and the Mississippi Legislature. “Funds were secured over time and include support through the Resources and Ecosystems Sustainability, Tourist Opportunities, and Revived Economies of the Gulf Coast States Act (RESTORE) Act and from the State of Mississippi,” says Dr. Kelly Darnell, GCRL director. “Essential to this funding is the direct connection to state management goals including restoration, and supporting industry and the Mississippi economy.”

In addition to large-scale production, the hatchery will provide a platform for advanced research. “The OHRC was purposefully designed to balance commercial-scale production with advanced research needs,” say Blaylock and Gima. “The facility incorporates state-of-the-art systems, full-scale laboratories, and specialized research areas with arrays of tanks that can be configured into controlled, isolated, and replicated systems for conducting scientifically robust experiments that address relevant issues or bottlenecks in larviculture, genetics, disease management, and water quality.”

The project team—McCarty Architects, Aquaculture Systems Technologies, LLC, Innovasea Systems, Inc., Dan Hensarling, Inc., and TCMAC program managers Egan Rowe and Megan Gima—brings extensive expertise in marine systems design. “Aquaculture engineering and design is a specialized subset of skills compared to the broader construction and design industry but we are well connected with the sectors that possess the necessary skillsets,” say Darnell, Blaylock, and Gima. “Through the state bidding and procurement processes we’ve been successful at creating a project team with the necessary skillsets and expertise in aquaculture facility design and systems.”

Cultivating the next generation

Poised as an educational and research hub, the hatchery will provide hands-on learning for students at all levels while advancing sustainable aquaculture through adaptive, multidisciplinary management. Image: Courtesy of The University of Southern Mississippi

Beyond research and restoration, the hatchery is poised to become an educational hub. “The hatchery will create a wide range of student opportunities ranging from high school to graduate levels,” say Blaylock and Gima. “It will integrate with the Marine Aquaculture Demonstration Initiative to provide work-based learning experiences for high school aquaculture CTE classes and undergraduate interns. It will further serve as a platform for applied research and workforce training for USM graduate students to build the next generation of aquaculture professionals.”

Looking ahead, the team acknowledges that operational success will require continuous learning and adaptation. “This facility will be unique. As a result, maintaining the recirculating hatchery will require adaptive management to respond to evolving challenges,” Blaylock and Gima say . “Experience will drive innovation and long-term sustainability. Success will depend on the ability of well-trained staff to bring a variety of skills in biology, engineering, mechanical expertise in electrical and plumbing systems, systems management, and human resources to bear.”

By combining innovation, research, and hands-on learning, the new oyster hatchery at Southern Miss is helping chart a path toward a healthier, more sustainable Gulf Coast.