A High-Rise Laboratory That Redefines Research Infrastructure

KU Leuven’s new 30,000-square-meter BioScience Centre brings 500 researchers together in a 14-story high-rise that sets a new standard for sustainable, flexible, and collaborative lab design. Image: Frédérique Demeer

KU Leuven has inaugurated its new BioScience Centre—a 30,000-square-meter, 14-story facility in Leuven, Belgium, designed to house 500 researchers across the life sciences. More than just another academic research building, the BioScience Centre serves as a case study in integrating sustainability, flexibility, and social connection into a single high-rise laboratory environment.

The project team included KU Leuven (client, lab planner, and relocation services); Proof of the Sum, SVR-architects (architecture); Exilab (part of Sweco), Studieburo De Klerck (engineering); CIT Blaton nv (structural works), Imtech Belgium nv (technical works), Kone Belgium (elevators), POELS nv (finishing) (construction); and Potteau nv, Motix, Thermo Fisher Scientific—Asecos (lab furniture/equipment).

At the start of the project, the team compiled a detailed spreadsheet of each research group's lab needs, including space requirements. Working with principal investigators, they mapped connections between related groups to co-locate them on the same floor or in nearby locations. This approach ensured an efficient and optimized allocation of laboratory space.

"To ensure long-term flexibility, unfinished 'shell' spaces (casco) were incorporated on various floors to accommodate future growth or downsizing of research teams," says KU Leuven lab planner Kristin Van de Plas. "These efforts culminated in a color-coded layout plan in which zones were assigned to the different research groups, who were then invited to further define their specific spatial requirements."

The next phase focused on refining the laboratory design, continues Van de Plas. "This involved consultations with research groups: the lab and facility managers, together with the PIs and HSE of KU Leuven. Input was gathered through site visits to current labs, equipment lists, and ongoing dialogue regarding scientific needs. Throughout this process, the project team applied a critical perspective, striving to find the most effective and efficient solutions—recognizing that not all user demands could be accommodated due to budgetary constraints."

Throughout this process, the project team applied a critical perspective, striving to find the most effective and efficient solutions. This staged approach ensured the facility could adapt even before occupancy, a lesson in how planning can remain dynamic in long, complex projects.

Designing for flexibility and future-proofing

The BioScience Centre was designed for long-term adaptability, with modular lab layouts, scalable mechanical and electrical systems, and spare capacity built into infrastructure to ensure the facility can evolve with future research needs. Image: Courtesy of KU Leven

"At an innovative institution like KU Leuven, scientific research evolves rapidly—often shifting focus or requiring new technologies. As a result, designing future-proof infrastructure was a core priority to ensure the building could adapt to changing scientific needs without major renovations," says project engineer Sofie Van Den Bergh.

This flexibility was achieved through several key technical strategies:

Ventilation loop system: The central air system was designed as a loop, allowing for future adjustments in airflow rates to be easily upscaled or modified without requiring any structural changes.

Scalable cooling and heating capacity: Each floor is equipped with additional capacity for local climate control, enabling tailored environmental conditions as research needs evolve.

High-capacity air handling units: Six AHUs, each delivering 50.000 m³/h, provide robust and scalable ventilation for various laboratory configurations.

Expandable electrical infrastructure: The power distribution system on each floor includes spare capacity, allowing for the easy addition of new lab equipment.

Gas systems: Special gas supply areas are designed for easy expansion or reconfiguration.

Modular lab layout: Laboratories are arranged on a modular grid, with technical systems following the same logic. This means individual labs or spaces can be modified or reconfigured without impacting adjacent areas.

By aligning technical infrastructure to a modular grid, labs can be reconfigured without major structural work. Spare capacity in mechanical and electrical systems ensures the building won't be obsolete when research needs evolve.

For other institutions, the takeaway is clear: technical resilience and adaptability should be embedded in infrastructure, rather than being bolted on later.

Technical and logistical Challenges

Designed as a “social building,” the BioScience Centre uses shared living spaces, flexible work areas, and central communal facilities to foster connection and collaboration among its 500 researchers. Image: Courtesy of KU Leven

The BioScience Centre was conceived as a "social building." For KU Leuven, consolidating 500 researchers into one vertical facility carried the risk of compartmentalization. The design team countered this by integrating open "living spaces" every two or three floors, shared coffee areas, and flexible workstations.

Project manager Frédérique Demeer emphasizes, "Knowledge sharing, communication, and encounter form the foundation for a social building and innovation." The central vertical backbone of the building serves as a hub for interaction, reinforced by shared facilities such as an auditorium, cafeteria, and terrace.

Even laboratory design supported this goal. "Where possible, open wet labs were created," notes Demeer. Transparency between office corridors and laboratories fosters both daylight penetration and a sense of connection between workspaces.

For planners and architects, the lesson is that social design principles—often associated with office environments—can be successfully applied to lab buildings to encourage collaboration.

Constructing a 14-story high-rise laboratory was not without its hurdles. From fire regulations to ventilation strategies, the team had to strike a balance between density and stringent safety standards.

"One of the main challenges was accommodating a large volume of research activity on a relatively small site footprint," says Van Den Bergh. "This led to the decision to design a high-rise laboratory building, which introduced several significant technical and regulatory hurdles." For example, Belgian fire codes required additional measures that initially conflicted with the goal of flexibility. The design team resolved this by opting for a fully sprinklered laboratory environment—unusual for labs, but necessary to maintain openness and transparency within the high-rise.

Centralizing the air handling units on the seventh floor was another novel solution. Placing major infrastructure in the building's core allowed for more undersized ductwork, improved energy efficiency, and a chimney-like central exhaust system.

Sustainability in practice

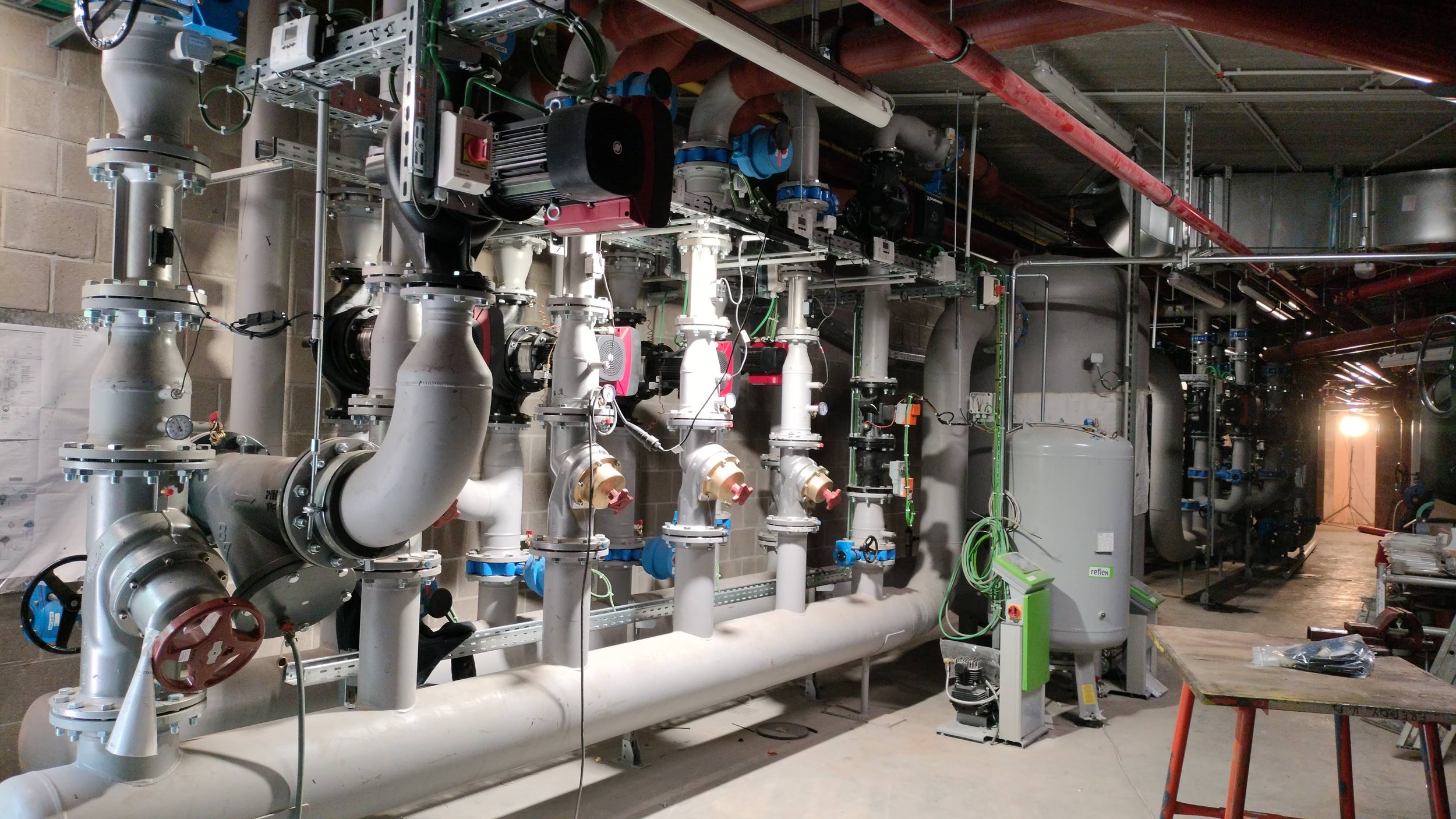

The BioScience Centre’s carbon-free heating and cooling system was designed to handle the highly dynamic thermal loads of laboratories, ensuring year-round efficiency without fossil fuels. Image: Courtesy of KU Leven

Sustainability was not treated as an add-on but as a guiding principle. The building incorporates carbon-free heating and cooling systems, geothermal boreholes, reversible heat pumps, solar panels, and rainwater recovery systems.

As Van Den Bergh says, "Carbon-free heating and cooling was a fundamental design principle from the start. Given the continuous and simultaneous demand for both heating and cooling in a laboratory environment throughout the year, the system had to be capable of handling highly dynamic thermal loads."

This system, managed by a smart Building Management System, eliminates fossil fuel use and positions the BioScience Centre as a near net-zero facility.

Building such a dense, vertical laboratory presented its own lessons for the future. Demeer says, "A high-rise construction presents demanding challenges in terms of fire regulations, structural stability, and evacuation procedures. These complexities are further amplified by the building's function as a laboratory facility, where experiments and research activities generate elevated risks."

For institutions planning similar large-scale laboratory projects, the BioScience Centre illustrates both the opportunities and the risks associated with vertical densification. It can unlock efficiencies and preserve green space, but requires careful attention to safety and user reassurance.

As KU Leuven prepares to welcome its first researchers into the BioScience Centre in 2026, the facility offers lessons in engaging stakeholders, embracing densification, and embedding sustainability and adaptability from the ground up.