Navigating the International Building Code’s “New” Requirements for Higher Education Laboratories

University laboratories play a crucial role in attracting top researchers, fostering the development of promising students, and supporting innovative scientific exploration. At the same time, they contain significant hazards that can compromise the safety of students and faculty and the integrity of their work.

Designing and operating safe and compliant laboratory spaces requires staying current with the latest building codes. In 2018, the International Building Code (IBC) introduced new requirements for higher education laboratories to better address the realities of these spaces and align with current practices. Since then, these updates have been carried over to the 2021 and 2024 versions. However, many states are only now transitioning from the 2015 IBC (or earlier) to the more recent versions, leaving owners, design teams, architects, and engineers to catch up with implementing the new provisions.

New IBC requirements benefit higher ed laboratories

Prior to the 2018 IBC, Section 414 of the International Building Code served as the primary reference for designing higher education laboratories. This section provides rigorous requirements for buildings and structures that manufacture, process, dispense, use, or store hazardous materials. However, given that higher education facilities differ from laboratories that handle hazardous materials, the provisions of Section 414 were seen as overly limiting, necessitating changes that would address factors unique to higher education labs.

As a result, the 2018 IBC updates introduced Section 428, which altered the provisions for facilities designated as “higher education laboratories,” allowing for increased chemical volumes. Under Section 428, as long as the facility meets the requirements for IBC Section 428 and Chapter 38 of the International Fire Code (IFC), higher education laboratories can exceed the maximum allowable quantities (MAQ) of hazardous materials in control areas or laboratory suites without requiring classification as a Group H occupancy.

This change essentially allows higher education laboratories using hazardous materials to maintain Group B occupancy status, which has less restrictive requirements for building structural elements. IBC versions 2018, 2021, and 2024 define higher education laboratories as:

Laboratories in Group B occupancies used for educational purposes above the 12th grade. Storage, use and handling of chemicals in such laboratories shall be limited to purposes related to testing, analysis, teaching, research or developmental activities on a nonproduction basis.

IBC Section 428 and IFC Chapter 38 further outline the specific requirements that must be met to exceed the MAQ. These provisions cover infrastructure, fire protection, power, emergency egress, hazardous materials, and ventilation.

Maximum allowable quantities have increased

In the 2015 and earlier versions of the IBC, all laboratories, including higher education laboratories, needed to comply with the maximum allowable quantities of hazardous materials as outlined in Section 307, Table 307.1(1) and as modified by the use of storage cabinets, control areas, and automatic sprinkler systems. However, the code requirements for control areas included in Section 414 of the earlier versions of the IBC were at odds with the current design and operational practice of higher education facilities.

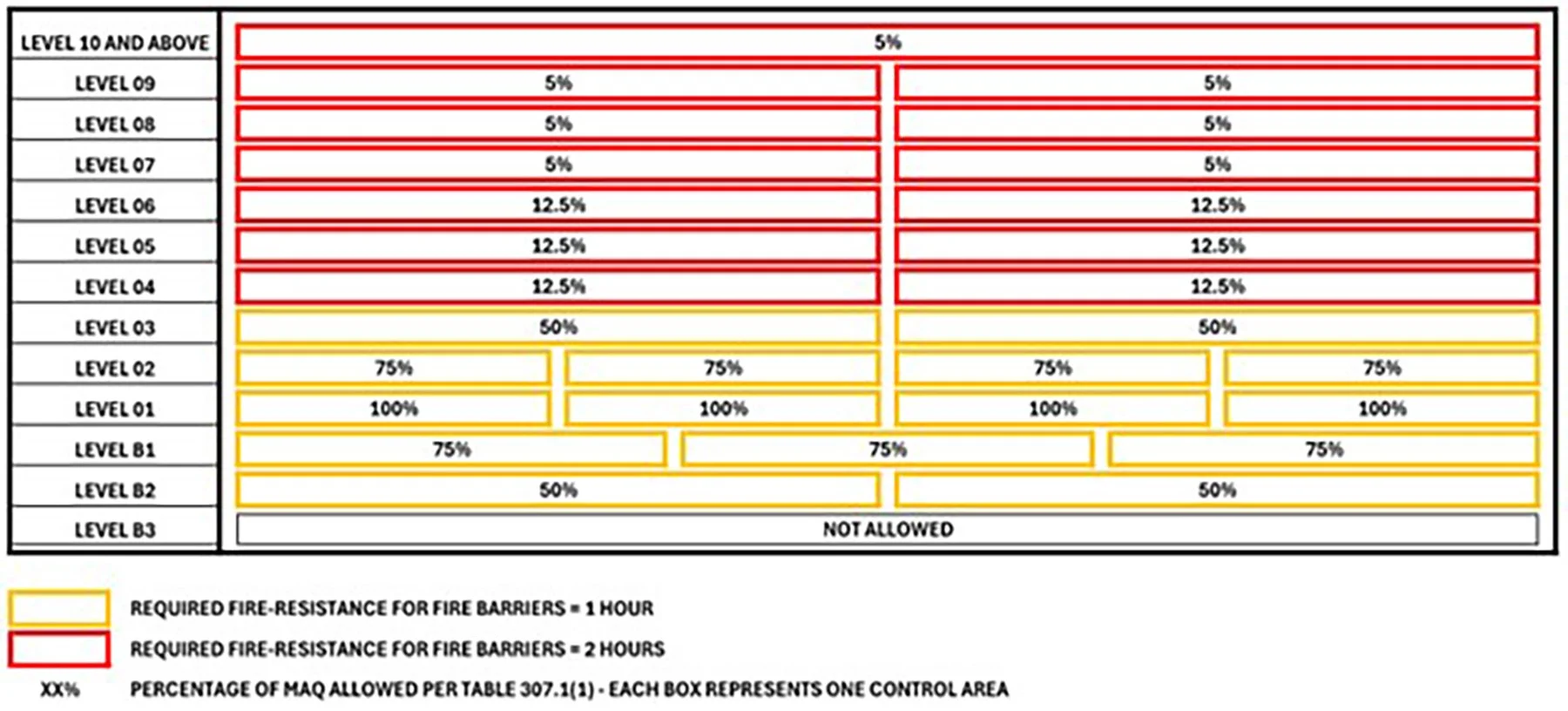

The IBC defines control areas as “[s]paces within a building where quantities of hazardous materials not exceeding the MAQs per control area are stored, dispensed, used or handled.” Section 414 requirements only allow 100% MAQs per control area on the first floor, where classrooms and other public-facing amenities are ideally located in higher education buildings. The MAQs quickly drop off above the third floor, reducing from 50% MAQ per control area on level 3 to 12.5% MAQ on level 4 and 5% for level 7 and above (see Figure 1).

Figure 1: 2015 IBC Requirements for Design and Number of Control Areas

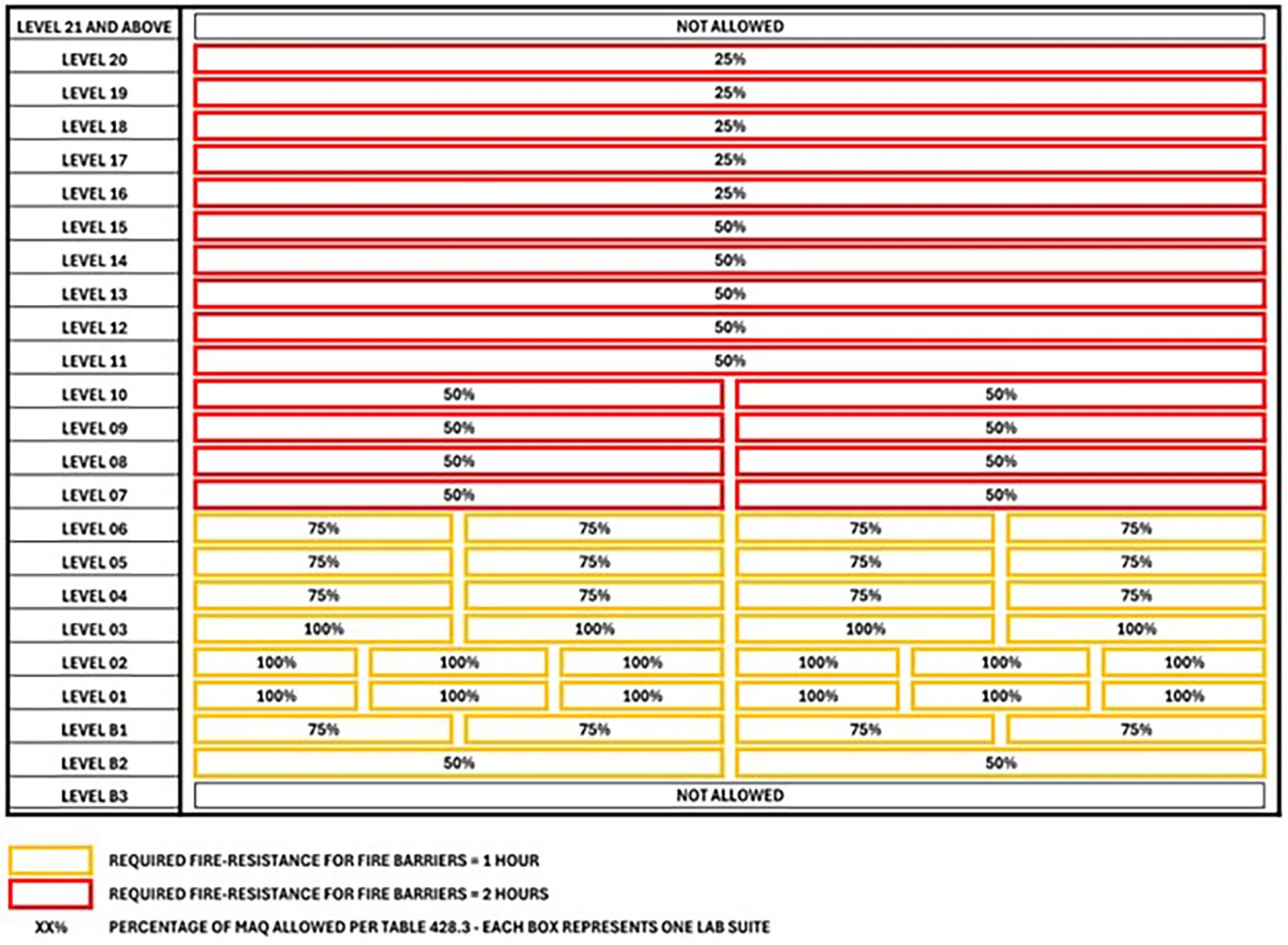

University laboratories generally store and use chemicals in smaller quantities for research and testing, not for large-scale production. Because of this, the new requirements in Section 428 allow greater percentages of MAQs on each floor level compared to the earlier versions of the IBC. For example, the new provisions now allow levels 1 through 3 to have 100% MAQs per control area, with 25% to 50% MAQs per control area for levels 7 through 20 (see Figure 2).

Figure 2: 2021 IBC Requirements for Design and Number of Laboratory Suites Per Floor

It is important to note that Section 428 uses the term “laboratory suite” instead of “control area.” The IBC defines a laboratory suite as a “fire-rated, enclosed laboratory area providing one or more laboratory spaces within a Group B educational occupancy that includes ancillary uses such as offices, bathrooms, and corridors that are contiguous with the laboratory area, and are constructed in accordance with Section 428.”

Code provisions must be met to exceed MAQs

As mentioned, laboratories can exceed the maximum allowable quantities of hazardous materials provided they meet additional code requirements in IBC Section 428, IFC Chapter 38, and NFPA 45 for hazardous material safety, emergency power, ventilation, floor construction, and fire protection.

Hazardous materials: General safety provisions must be followed when handling and storing hazardous chemicals in laboratories. Higher education facilities need to ensure that:

Chemical safety reviews, including operating and emergency plans, are performed by laboratory safety personnel, such as the university environmental health and safety group, or a hazardous materials consultant.

Chemical handling, such as receiving, unpacking, and dispensing of hazardous materials, is completed by trained personnel.

All containers and above-ground tanks have hazard identification signs as required by NFPA 704.

Equipment, machinery, and detection systems are maintained in operable condition, and any defective or damaged containers are repaired or disposed of.

Time-sensitive materials are dated and managed in accordance with NFPA 45.

Liquid-tight flooring is installed in portions of labs where hazardous materials are present. The intent of this requirement is to prevent spills from penetrating the floor and contaminating the concrete slab or other subfloor materials. Any floor penetrations must also be sealed to prevent the transfer of hazardous material to the subfloor or floor levels below the laboratory.

Fire safety, ventilation, and power requirements: As outlined in Section 903 of the IBC and IFC, buildings utilizing laboratory suites must be fully sprinklered under NFPA 13. Additionally, ventilation designs for labs must comply with Chapter 7 of NFPA 45, which has key provisions such as:

Reduced operational modes must be used to prevent large pressure differentials that could prevent egress from the building.

Exhaust ducts from different laboratory units (or laboratory suites) must be ducted separately to a mechanical room, shaft, or point outside the building before being manifolded together in a common exhaust duct system.

Fire dampers and smoke dampers are not allowed; therefore, fire barrier penetrations must be protected by other means, such as a 22-inch subduct.

Standby or emergency power must also be provided where laboratory suites are located below grade or above the sixth story above grade. This provision applies to mechanical ventilation, temperature control, alarm, and detection systems serving those areas.

Keep higher ed labs safe and compliant

The IBC’s code updates for higher education laboratories now more closely align with the unique realities of how these buildings are organized and function. As more states adopt the 2018 IBC and later editions, owners, architects, design teams, and engineers need to remain proactive in understanding and implementing these requirements.

Additionally, as many states and localities amend the International Building Codes to create their own state or local code, close review of any local jurisdictional requirements or modifications to the IBC is imperative. Doing so will ultimately lead to safe and compliant higher-ed laboratory spaces, where scientific exploration thrives.