Inside a New Lab Built to Eliminate Bias in Taste Evaluation

Tasting stations inside the sensory lab. Image: Copyright Nutriswiss AG

In April 2025, Nutriswiss AG launched its new sensory laboratory in Lyss, Switzerland, designed to provide the ideal environment for the rigorous evaluation of oils, fats, and collagen peptides. The facility embodies best practices in sensory research, focusing on eliminating environmental interference to ensure panelists can accurately assess product quality.

Laboratory manager Michèle Béatrice Suter shares insights into the unique design considerations required for evaluating these products. “These products have an impact on the required equipment. For sample preparation, a refrigerator, heating cabinet and microwave are sufficient. The sensory laboratory is equipped with water baths that can be heated to 60 degrees C, as some samples solidify at lower temperatures and could not be tasted without heating. Collagen proteins are tasted at room temperature and do not require any specific equipment.”

End-user input shapes layout and features

Preparation room for the samples. Image: Nutriswiss AG

The project benefitted from direct collaboration with sensory scientists and customers to ensure the lab’s design met practical needs. Suter explains, “For the evaluation of some products, we collaborated with customers to develop the appropriate assessment, and employed various standards to design the equipment and room layout.” This user-driven approach ensured the lab could support multiple product types while aligning with established sensory evaluation standards.

A core challenge in sensory lab design is eliminating external influences that could bias results. Nutriswiss addressed this with thoughtful architectural and engineering strategies. “The tasting room is located next to the offices, away from noisy production machines and unpleasant odors. Sunlight has been completely excluded to eliminate any disruptive light influences, and a white light lamp provides standardized lighting at all times. In addition, red and UV lamps have been installed to exclude certain optical influences, enabling purely sensory tasting. The room has also been decorated in the most neutral colors possible,” Suter says.

This meticulous control of environmental factors—light, sound, odors, and even décor—helps sharpen panelists’ senses and ensures consistency across evaluations.

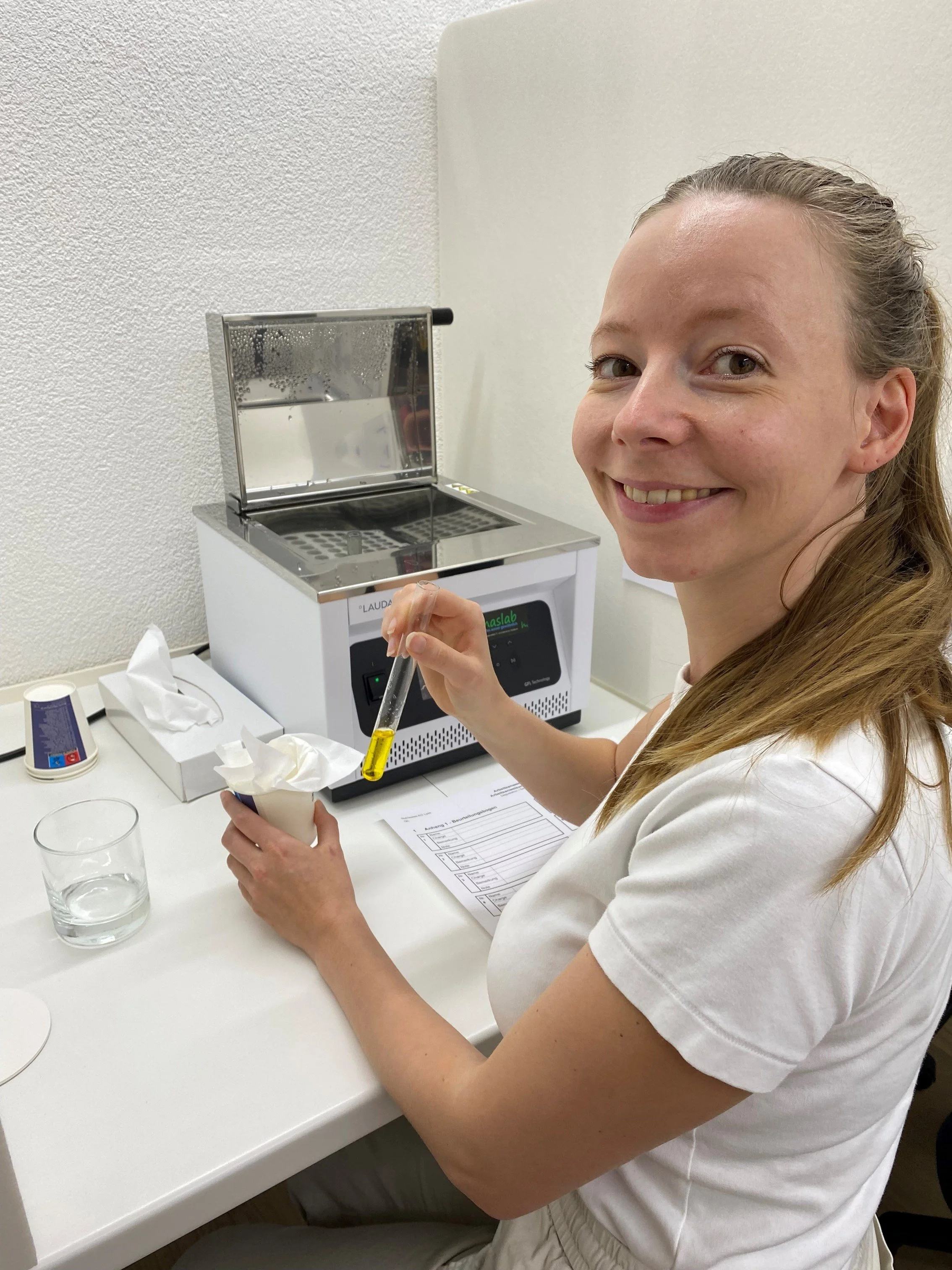

Dominique Schmid, research & development specialist, tasting samples in the new sensory laboratory. Image: Copyright Nutriswiss AG

Designing to support flexibility and group collaboration

The lab’s design accommodates a diverse range of tasting needs, supporting not only Nutriswiss’s oils and fats but also collagen peptides from sister company NutriFine AG. Suter notes, “The preparation room can be expanded at any time. Thanks to its layout, the sensory lab is suitable for tasting a wide variety of foods.” This multi-purpose flexibility is vital as the lab serves as a shared resource within the Centravo Group and will facilitate future collaborative tastings with external partners.

A modern sensory lab also depends on digital systems for data management. Nutriswiss has implemented the Limsophy LIMS system to link tasting results directly to sample and batch information, enhancing traceability and quality control. Suter explains, “The relatively new Limsophy LIMS system will have a significant impact on laboratory workflows, as it will facilitate the transfer of measurement results via interfaces. However, this has not yet been fully realized.” This points to ongoing opportunities to optimize digital workflows in sensory labs.