Microsoft Builds World-Class Facility to Advance Topological Qubit Research

Microsoft’s expanded Lyngby Quantum Lab in Denmark enables on-site fabrication of Majorana 1 topological qubits, supporting faster iteration and scalable quantum research. Image: Courtesy of Microsoft Corporation

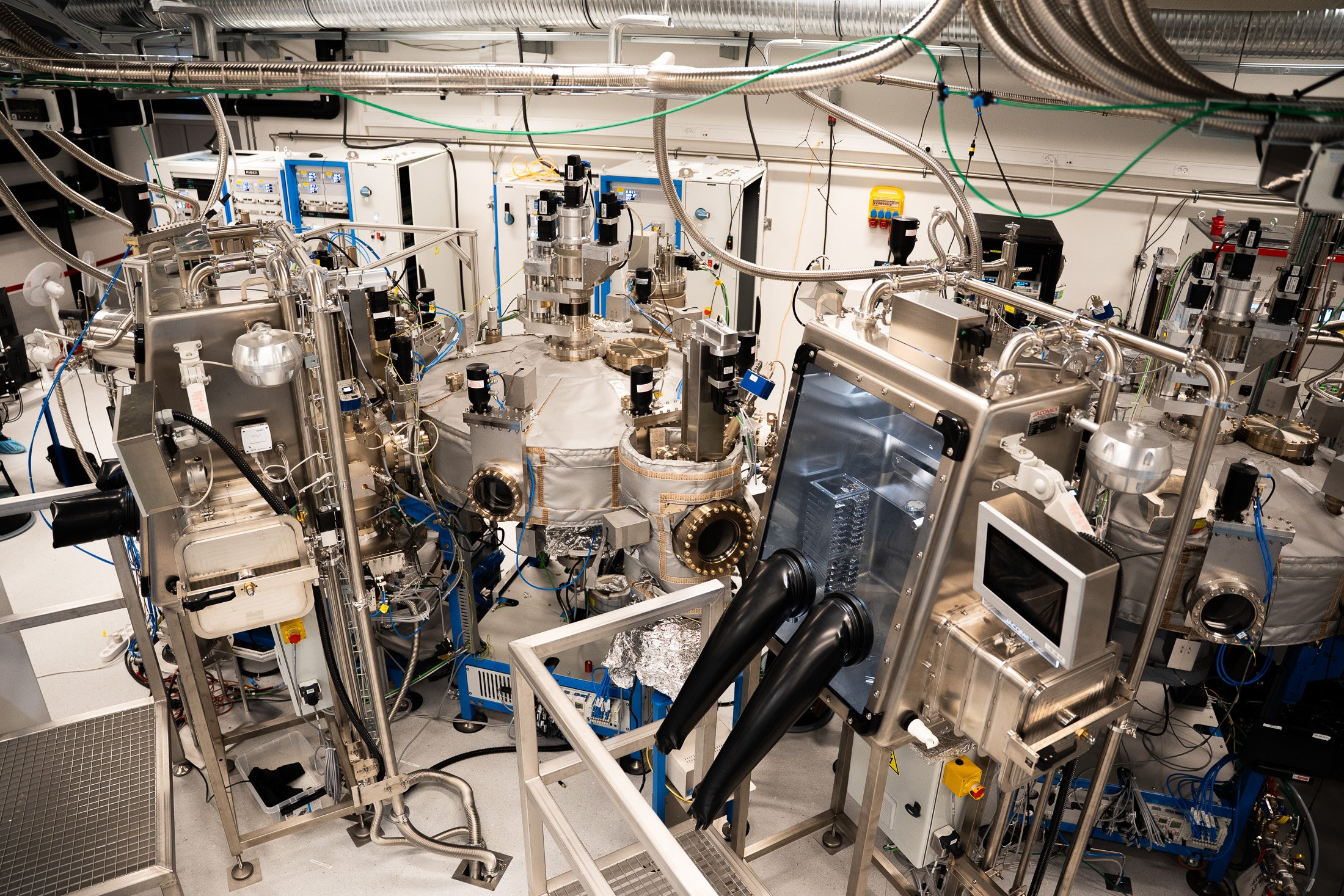

Microsoft has taken a significant step forward in its mission to develop general-purpose, fault-tolerant quantum computing with the expansion of its Quantum Lab in Lyngby, Denmark. Marking the company’s largest quantum site globally and its second facility in Denmark, the new lab reinforces Microsoft’s long-term commitment to partnering with Europe to accelerate the development of scalable quantum technologies. The investment in Lyngby pushes Microsoft’s total quantum investment in Denmark past DKK 1 billion (about $155 million USD), reflecting a strategic commitment to both scientific innovation and European collaboration.

At the heart of this expansion is Microsoft’s Majorana 1 chip, the world’s first quantum processing unit powered by a topological core. Designed to scale to millions of qubits on a single chip, Majorana 1 embodies Microsoft’s unique approach of combining deep physics with engineering at scale. The Lyngby lab has played a central role in the chip’s development, and the new facility now allows the full fabrication of these topological qubits to occur on-site, enabling researchers to iterate faster, achieve higher yield, and accelerate progress from decades to years.

People-first lab design

One of the defining features of the Lyngby expansion is the emphasis on human-centered design. Geoff Gardner, principal research manager at Microsoft Quantum, explains the rationale behind the lab’s layout and planning: “What we sought to do with our Lyngby quantum lab in Denmark was to put people first—including our people who would be working in this lab as an extension of their existing space next door, the colleagues who would be working to activate this lab in the design and tool installations, as well as the people who live in the proximity of this lab (the residents of the building and of the town). For me, I love the focus on people. The high-fidelity interaction between the technical team members supports our fabrication requirements.”

The lab brings together physicists, material scientists, micro- and nanofabrication experts, and software engineers from over 20 nationalities, many holding PhDs in their respective fields. By designing spaces that support collaboration among diverse disciplines while maintaining high-precision lab workflows, Microsoft has created an environment where rapid innovation can occur without sacrificing the strict control needed for topological qubit fabrication.

Cleanroom innovation and precision control

The Lyngby lab’s cleanroom combines ultra-controlled conditions, AI monitoring, and protective equipment to safeguard both topological qubits and researchers while supporting sustainable operations. Image: Courtesy of Microsoft Corporation

Central to the lab’s operations is a world-class cleanroom environment, engineered to provide ultra-controlled conditions for sensitive quantum experiments. “Cleanrooms maintain ultra-controlled conditions—temperature, humidity, airflow, and particulate levels—so that fabrication steps can occur without interference. The sensitivities are most likely referenced as ‘cleaner than a standard operating room’ in layperson descriptions,” Gardner says.

Microsoft’s cleanroom design incorporates international nanofabrication standards along with advanced airflow systems and AI-enabled monitoring for predictive contamination control. This approach ensures that both the qubits and the people working in the lab are protected. Full-body protective suits, or “bunny suits,” shield employees even though most processes occur within fully contained equipment. Furthermore, the lab’s environmental systems are designed to return air and non-potable water to the local environment in a state that meets or exceeds regulatory standards, supporting Microsoft’s broader commitment to sustainable operations.

Gardner highlights the precision required in quantum fabrication: “When you are writing at the level of nanometers, and even at the level of individual atoms, you need to control the tool and the environment to that level as well (and for context, one human hair is about a million carbon atoms wide).” Temperature, vibration, and electromagnetic field control, combined with redundant infrastructure and careful cleanliness protocols, allow the lab to achieve high yield and error-resilient processes crucial for topological qubit development.

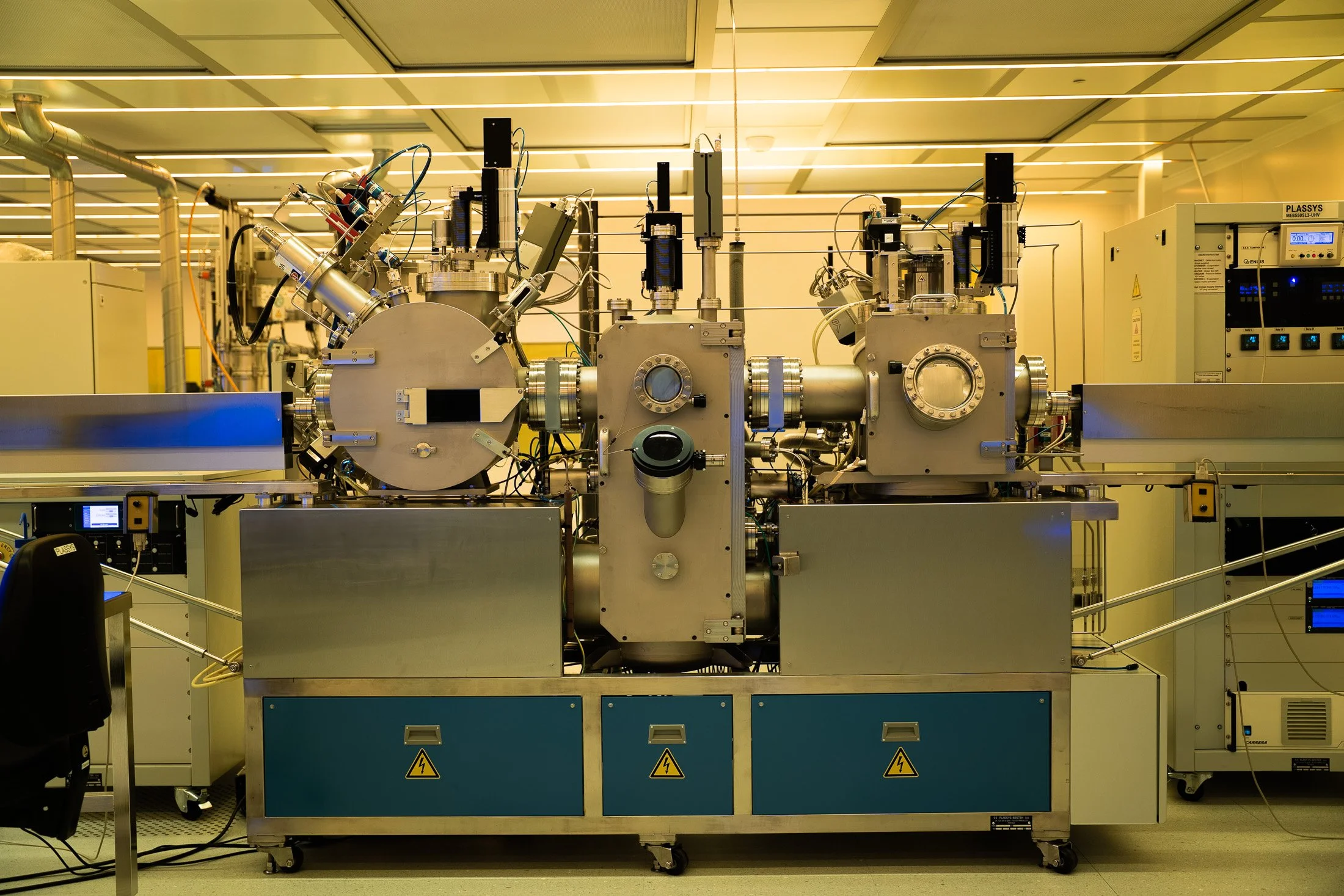

Integrating advanced instrumentation and AI

AI-enabled tools at the Lyngby lab monitor equipment, optimize workflows, and support researchers in rapidly iterating experiments while maintaining precision and reproducibility. Image: Courtesy of Microsoft Corporation

Beyond physical infrastructure, the Lyngby lab leverages AI to optimize both research workflows and facility operations. AI-enabled tools support predictive contamination control, pre-installation simulations, and continuous monitoring of equipment.

“Ultimately, the aim of AI is to improve the scientific process by first helping to protect the scientists working in these labs and then optimizing their workflows and plans so that they can focus on the key innovation and goals that bring them into the lab,” Gardner says.

The lab’s instrumentation is fully integrated with Microsoft’s data collection and analysis infrastructure. Each piece of equipment generates real-time data, fed into cloud and AI systems that can provide confidence scoring for processes without requiring additional metrology. This approach allows researchers to quickly identify and address potential issues, dramatically accelerating experimental iteration while maintaining quality and reproducibility.

Collaborative workflows and future-proofing

The Lyngby facility was designed with collaboration and flexibility in mind. Workflows are logically grouped to promote efficient interaction among physicists, engineers, and software developers while still isolating critical fabrication processes. Gardner says, “Grouping logical workflows together while still protecting and isolating necessary equipment” was key to balancing collaborative interaction with the precision demands of topological qubit fabrication.

Microsoft also planned for future growth, ensuring that the lab can accommodate new technologies and increased capacity without disrupting ongoing operations. Gardner says, “Leaving room for future scale includes not just equipment but also utilities such as power and/or gasses, and grey spaces for storage and loading.” By anticipating future needs, the facility provides long-term flexibility and a strong return on investment while minimizing operational disruptions.

Enabling breakthroughs in quantum computing

Microsoft’s Majorana 1, the world’s first topological-core quantum processor, can now be fully fabricated at the expanded Lyngby lab to accelerate scalable qubit development. Image: Courtesy of Microsoft Corporation

The expanded Lyngby lab represents more than a technical achievement—it is an enabling platform for the next generation of quantum research. By consolidating previously separate labs for packaging, lithography, and imaging, Microsoft has created a single, integrated environment that accelerates iteration and maximizes yield. “The facility is an enabling part of the research. It needs to be considered at this fundamental level, on par with human resourcing, device or component design, equipment, and data infrastructure,” Gardner says.

In addition to advancing Microsoft’s Majorana 1 chip, the lab supports broader European quantum ambitions. Microsoft collaborates with leading institutions such as the Niels Bohr Institute and the Technical University of Denmark (DTU) to develop materials and devices that protect quantum information and reduce errors. The facility also contributes to QuNorth, a Nordic quantum initiative aimed at operationalizing logical qubits through a partnership with Atom Computing, further cementing Denmark’s role as a European and global hub for quantum research.

Microsoft’s expanded Lyngby Quantum Lab highlights the ways that specialized laboratory design supports high-precision research. The facility integrates people-focused layouts, AI-enabled instrumentation, advanced cleanroom systems, and collaborative workflows to enable researchers to concentrate on experimentation and iteration in topological qubit development. The expansion also contributes to Denmark’s role as a hub for quantum research, providing infrastructure that supports both current projects and future growth. The Lyngby lab reflects the intersection of scientific goals, technical requirements, and careful lab planning, offering insights into how research facilities can balance precision, flexibility, and operational efficiency.

As Gardner says, “Planning maintenance and operation of the facility with the right type of people is important. Otherwise, researchers will need to focus their attention away from research to the facility. The facility is an accelerator; by bringing everyone together we increase the pace and quality of our research.”