Battery Lab 2.0: Lessons in Planning, Building, and Moving Into a High-Tech Research Facility

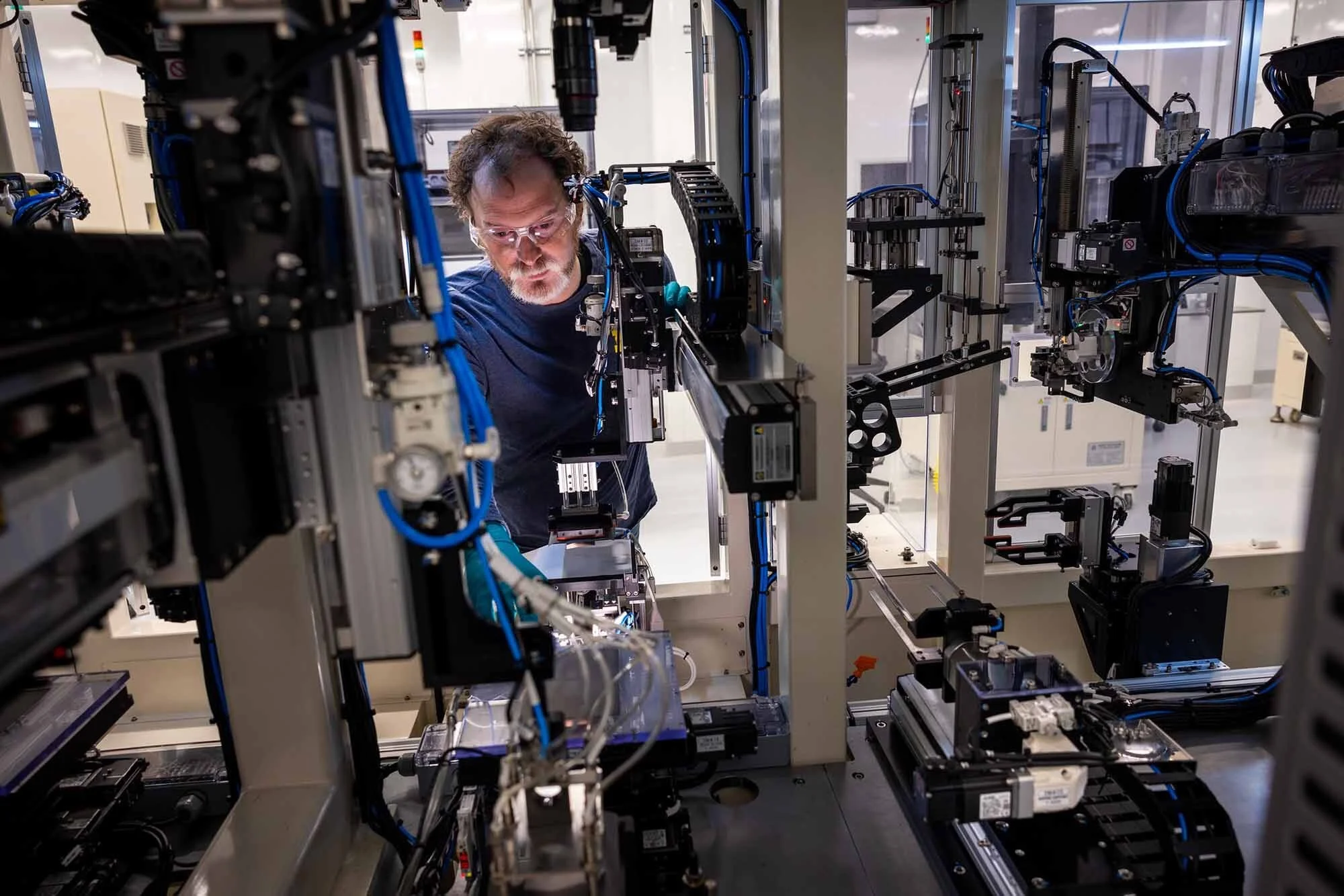

Greg Less, director of the U-M Battery Lab, works in the University of Michigan’s new Battery Lab facility. Image: Marcin Szczepanski, Michigan Engineering

The University of Michigan has officially opened Battery Lab 2.0, a 4,000-sf expansion that doubles down on the university’s commitment to advancing battery technology and bridging the notorious “valley of death” between research and commercialization. The new facility, located on Ellsworth Road near Ann Arbor’s southern border, provides industry and academic researchers with expanded space, advanced equipment, and a flexible environment designed to accelerate the pace of innovation.

The expansion marks a milestone moment for the university’s decade-long leadership in battery R&D. The original U-M Battery Lab, launched in 2014, was the first facility of its kind in the United States. Almost immediately, it became oversubscribed, with researchers from across the globe booking time to prototype and test lithium-ion and next-generation energy storage technologies. But as electric vehicles and renewable energy storage gained traction, demand soon exceeded the lab’s capacity.

Since its launch a decade ago as the nation’s first university-based facility of its kind—and the only one located in the center of the auto industry—the U-M Battery Lab has played a pivotal role in advancing technologies that now power today’s electric vehicles. Growing demand, however, has consistently exceeded the lab’s capacity, prompting the expansion to Battery Lab 2.0 and providing researchers with additional space and resources to accelerate innovation.

The project team included SmithGroup (architecture firm and lab planner), CBRE (project management), Ideal Contracting (construction firm), Energy Tech Solution (cell fabrication equipment), Scientific Climate Systems (dry room design), and Manz AG (laser welder).

Designing for real-world feedback

From the start, the design of Battery Lab 2.0 was shaped by direct input from users. After seven years of continuous operation at the original site, staff had accumulated extensive feedback from academic researchers, startups, and automakers.

“The original Battery Lab had been in operation for seven years with a steady stream of users, giving us feedback on what worked and what didn’t with the original design, as well as changes that were needed to keep abreast of advances in the Li-ion battery industry,” says Greg Less, director of the U-M Battery Lab. “Additionally, prior to finalizing any product specifications, we sent a survey out to our users asking them what cell sizes and formats would be most valuable to them.”

He notes that the survey received a wide range of answers, some of them unrealistic for a university-based operation, “There was a general consensus that we needed to make larger cells in both the pouch and cylindrical formats.”

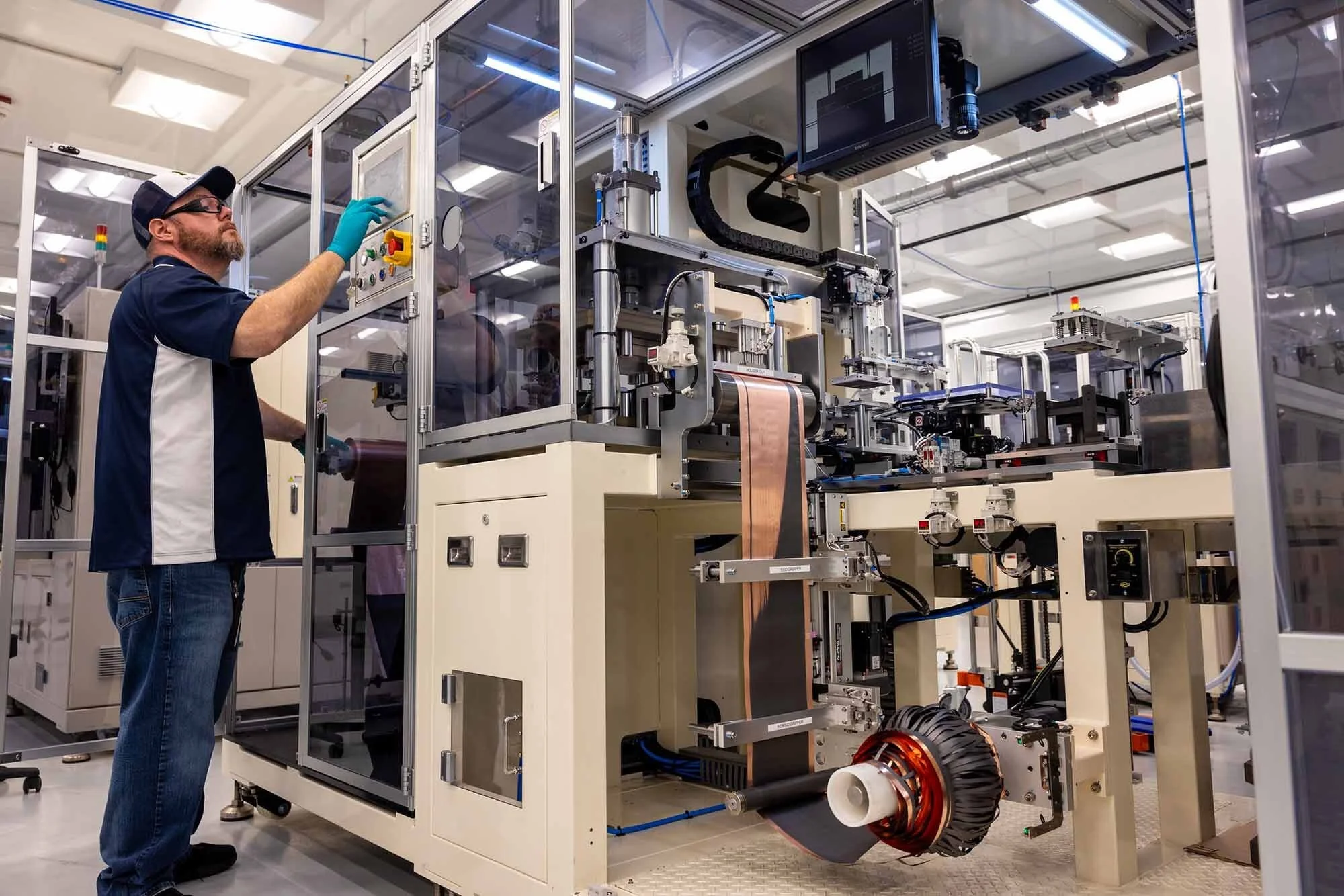

This direct line of communication influenced many of the key upgrades at the new site. Among them are a larger 30-liter mixing capacity, a six-meter coating system for electrodes, and the ability to produce both the widely used 21700 cylindrical cells and the 100×150-millimeter pouch cells—formats that mirror what’s deployed in today’s automotive applications.

Perhaps most importantly, the new facility includes a 4,000-sf dry room where the entire cell manufacturing process takes place in a tightly controlled low-humidity environment.

“The impact of moving our mixing and coating into the dry room can’t be understated,” Less says. “By having the whole cell manufacturing process inside of a dehumidified space we will be able to help our users manufacture cells using the latest Li-ion technologies, as well as next-generation energy storage solutions, such as lithium-sulfur and lithium metal cells.”

Navigating construction and off-campus challenges

Jason Jeppesen, Battery Lab engineer, uses Electrode. Image: Marcin Szczepanski, Michigan Engineering

Building an off-campus facility came with unexpected hurdles. While the university enjoys a certain flexibility when operating on its main campus, moving to a new jurisdiction introduced additional codes, hazard classifications, and facility requirements.

“There have been a number of challenges, starting with the jurisdiction that we chose to locate in—the university has a certain amount of leeway when operating on campus, but the off-campus location presented a new set of rules and challenges we needed to overcome,” Less explains. One significant barrier was related to cell cycling, which could have triggered costly building upgrades. Instead, the team decided to cycle cells at the original lab, transporting them between facilities when needed.

Beyond regulatory requirements, day-to-day operations also became more complex. “Being on-campus has many hidden perks that only become obvious when you move off campus and have to address things like janitorial services, landscaping, waste disposal, etc.,” Less says. “It’s definitely been eye-opening.”

To keep workflows aligned, staff were cross-trained at both facilities and modern communication tools—Zoom, instant messaging, and weekly team meetings—were leveraged to maintain cohesion. Battery Lab 2.0 was also staffed from the ground up, but not without careful planning. “All of the Battery Lab 2.0 staff had worked in Battery Lab 1.0 for at least six months before transferring to the new location. It’s important to have continuity of processes and procedures, so this was a critical decision,” Less says.

Supporting multiple users without conflict

Greg Less holds batteries made at the University of Michigan’s new Battery Lab facility. Image: Marcin Szczepanski, Michigan Engineering

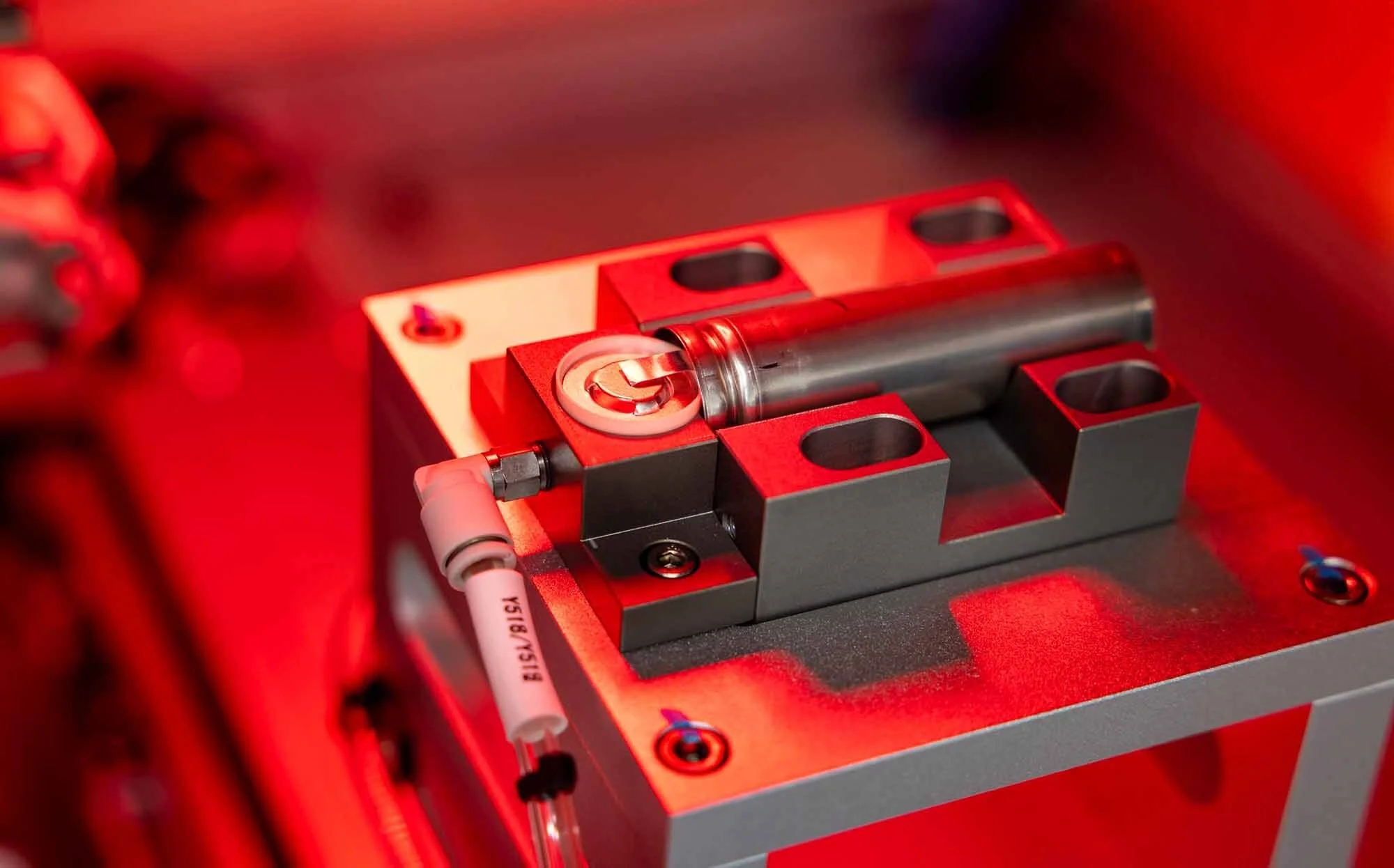

While the original Battery Lab remains fully booked, Battery Lab 2.0 was designed as a fresh start with entirely new equipment. Among the standout additions is an automated laser welder that allows researchers not only to build individual cells but also to assemble them into modules and full battery packs.

“The inclusion of a laser welder in our suite of tools opens a whole new area of research,” Less says. “By now offering a path toward making modules and packs, we are enabling our users to move one step closer to final product design and testing.”

This capability is crucial for bridging the final stages of development—helping startups, universities, and established automakers alike to validate their concepts under real-world conditions. Companies such as Ford, Mercedes-Benz, PPG Industries, and Nanoramic have already tapped into the U-M Battery Lab’s ecosystem to advance their R&D programs.

Given its open-access model, one of the lab’s biggest design considerations has always been maintaining confidentiality while serving a wide variety of users.

“Like our original Battery Lab space, we do our utmost to protect the intellectual property of our users. We have always had a policy of only one group in the space at a time, whether that is industry or academic. The only exceptions to this are when we have express permission from our users to allow a second group to share the space,” Less says.

This approach, coupled with professional staff support at every stage, ensures that both seasoned industrial engineers and early-stage startups can work in an environment that is intuitive, efficient, and secure.

Looking ahead to the future lab

A battery in the Positive Tab to Can Welding Machine (Laser Welding) at the University of Michigan’s new Battery Lab facility. Image: Marcin Szczepanski, Michigan Engineering

Battery Lab 2.0 is ultimately a bridge to something even bigger: a $60 million on-campus facility that will be added to the U-M Transportation Research Institute building. Funding for both the interim facility and the future expansion stems from Michigan’s $130 million contract establishing the U-M Electric Vehicle Center in 2023.

“Communication and timing is everything on these big construction projects,” Less says. “Deadlines and expectations need to be clearly communicated to all parties so that there are no surprises. This can be particularly challenging when working with foreign equipment suppliers who have different communication styles.”

Until that larger facility is realized, Battery Lab 2.0 stands as a testament to U-M’s adaptive approach—listening to users, overcoming regulatory and logistical hurdles, and investing in infrastructure that keeps the US at the forefront of energy storage innovation.

“By having all three of these facilities—the R&D Line, Pilot Line 1.0, Pilot Line 2.0, and module welding—we are effectively able to bridge the entire Valley of Death from innovation, to proof of concept, to scale-up, and finally product integration,” Less says.