A Historic Building Reimagined: Creating a Modern Life Sciences Facility in Rochester

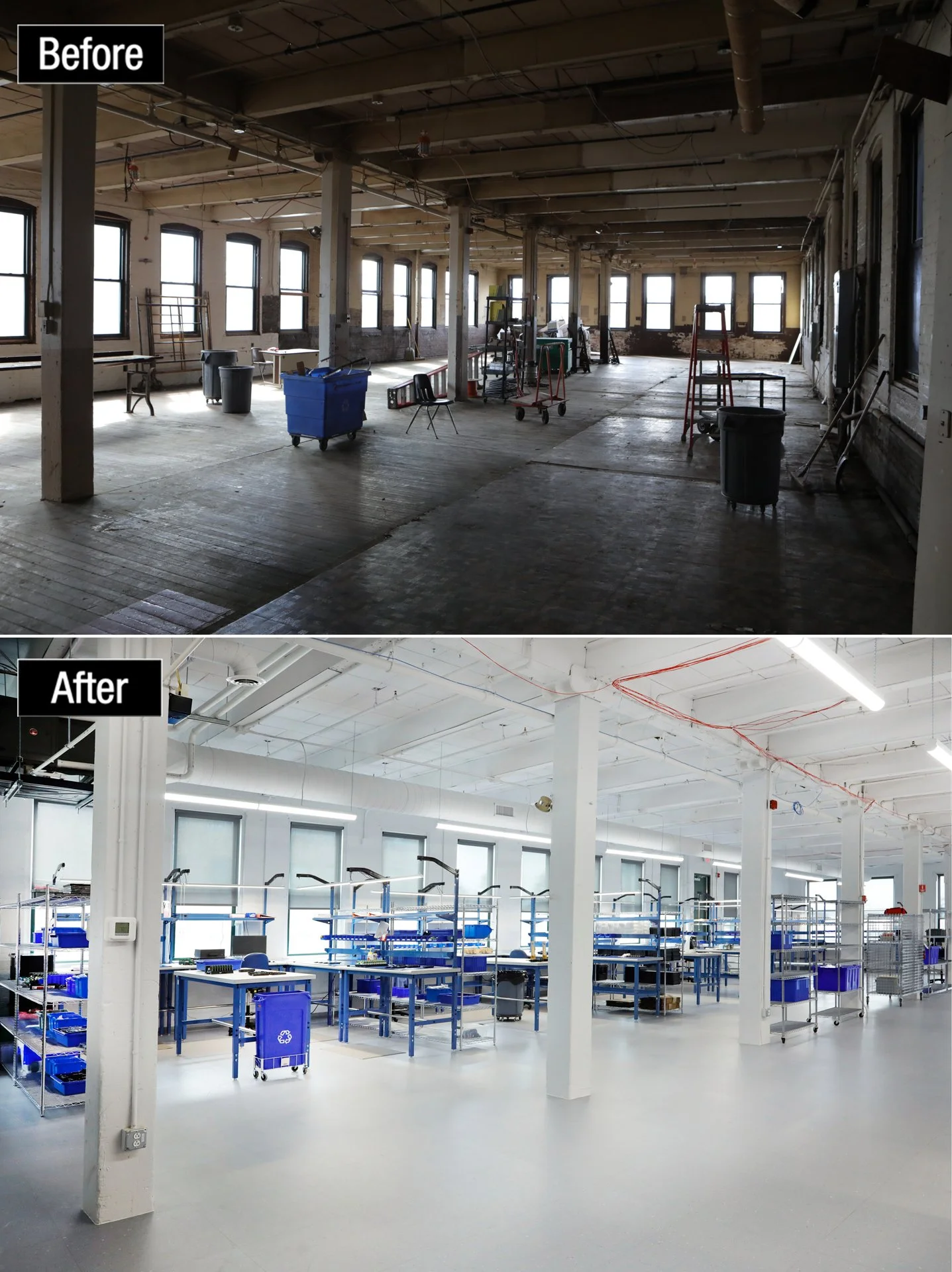

Before and after photos of the assembly room at G&H’s Innovation Hub for Life Sciences in Rochester, NY. Image: Courtesy of G&H

As the life sciences sector continues to demand faster, more seamless transitions from concept to commercialization, G&H has officially opened its new Innovation Hub for Life Sciences in Rochester, NY. Purpose-built to accelerate product development for medical technologies, the facility marks a significant expansion of G&H’s global capabilities—bringing its 45 years of engineering and manufacturing expertise from the UK to the North American market. Designed to support everything from early-stage research to ISO:13485-certified, high-volume production, the hub aims to streamline the path from idea to impact in the medtech space.

Lab Design News spoke with Ian McCutcheon, global R&D director at G&H, to better understand how the space was planned to support research, development, and manufacturing in the life sciences sector. The conversation explored decisions around layout, infrastructure, and functionality—particularly how the facility accommodates activities ranging from prototyping to high-volume production. The discussion also highlighted how the new site integrates existing capabilities like precision injection molding with expanded workflows tailored to medical device development.

Q: How was input from end users—including engineers, scientists, and production teams—gathered and incorporated into the design of the Innovation Hub? Were there any surprising insights from those conversations that shaped the final design?

A: G&H, through its Ashford facility, has 45+ years of both design and manufacturing experience under the belt, working with various business groups from startups to Fortune 500 companies on a global scale. This means we were able to translate this extensive experience into data that helped us set up the new G&H Innovation Hub for Life Sciences and adjust its layout to meet the needs of both staff and instrumentation. A production floor on the ground floor allows us to manufacture larger standing instrumentation, while upstairs we have installed working stations that facilitate the development of smaller benchtop and handheld equipment. Having an in-house R&D facility alongside manufacturing helps ensure both seamless knowledge transfer and also on-hand technical support. For the R&D section, we opted for a bright, airy designed office to help stimulate creativity and collaboration. The R&D team has easy access to the labs and tools that enable proof-of-principle and prototype building to technically derisk later designs and speed up development. In general, the new Innovation Hub has been designed as a modern office space, with elements such as sit-to-stand desks, modern IT equipment, and state-of-the-art teleconferencing systems that create an efficient and ergonomic workplace.

One conversation that helped shape the R&D area in particular was the desire to a have a kitchenette space which provides a comfortable spot for engineers and clientele to casually discuss projects in a more relaxed setting over freshly brewed coffee or tea. The informal aspect of connection has proven to increase trust, and promote a faster, more efficient information flow (e.g., Your Organization Is a Network of Conversations study from MIT).

Q: What design strategies were implemented to ensure the facility can adapt to rapidly evolving technologies and medtech manufacturing needs in the future?

Working station at G&H’s Innovation Hub for Life Sciences in Rochester, NY. Image: Courtesy of G&H

A: We adopted a dual design strategy for the Hub architecture, focusing on both preservation and innovation.

First and foremost, we relied on renovation as a design strategy, transforming a 100-year-old building in the city of Rochester into the current Innovation Hub structure. We preferred this approach because it represents a sustainable solution that galvanizes the local community (an important corporate value at G&H) and a financially responsible choice for the business. Broader considerations for this renovation project include the building’s proximity to potential future partners such as university research hubs, and associated health care and optics institutions, as our Innovation Hub encompasses a large optical component for medical equipment.

Simultaneously, we updated the space for a modern setting by including modular spaces, flexible utilities, and digital infrastructure readiness that can easily facilitate remote work and global reach (e.g., client conferencing). The production floor areas are modular in design and able to be flexible in size as the needs of a projects require. All areas are digitally serviced, as well as offering flexibility in terms of utilities such as power, compressed air, etc. Static dissipative flooring throughout the Hub space enables safe handling of sensitive electronic devices.

Q: How did the design team balance the integration of R&D, prototyping, and ISO:13485-certified manufacturing under one roof while maintaining efficient workflow and regulatory compliance? Did the hybrid nature of the facility require any unique architectural or operational planning solutions?

A: The G&H ITL portion of the building is segregated from the GS Optics area with key areas secured under access control. There are separate entrances to the building with guests required to pre-book and register upon arrival. Goods in and storage areas are separated, with the G&H ITL area having its own decontamination zone to allow onsite returns and servicing of medical and laboratory devices.

Q: What role did sustainability and energy efficiency play in the design and construction of the facility, especially given the high-volume production capabilities? Were any green building certifications or energy modelling techniques used?

The R&D lab working space. Image: Courtesy of G&H

A: At G&H, sustainable mechanical, electrical, and plumbing engineering systems form a crucial part of the overall building strategy, an approach that goes under our sustainability and development action plan for the entire group.

As the refurbishment was applied to an existing historic, brown-field facility, our emphasis was on working with the available building configuration. It is widely known that medical equipment manufacturing facilities are major energy consumers due to high-volume production needs that drive high electrical and cooling demands.

Being aware of the estimated energy and resource consumption of such an Innovation Hub, we incorporated sustainability-based decision making within the building restrictions in play. Low energy lighting has been employed throughout the facility, and a special recycling plan is in the works regarding different materials—even down to use of re-usable coffee cups, a plumbed water bottle filling station, etc.

Q: How is the facility preparing for the move-in process—particularly with the transition of specialized manufacturing equipment and sensitive lab instruments? What kind of coordination and testing will be done before operations go live?

A: In addition to the state validation processes and approvals, in-house projects have been transferred over from the UK facility (G&H | ITL in Ashford, UK, the parent facility for the G&H Innovation Hub in Rochester, NY) to help prove out systems and processes. The key word here is “validation”—our direction was to test the production capability using similar parameters as in our UK facility and check if the outcome can be delivered under the same quality standards. We did this by using a known gold-standard product. The auditing of these company facilities by both the inhouse quality and regulatory affairs team in the United States has enabled us to achieve full ISO:13485 accreditation.

Q: What measures were taken to ensure a smooth onboarding and workspace setup for staff moving into the new facility, especially those transitioning from other G&H locations or new hires? Any staff-centric design choices like ergonomic labs, wellness spaces, or collaborative environments?

Before and after photos of G&H’s Innovation Hub for Life Sciences in Rochester, NY. Image: Courtesy of G&H

A: Within the R&D office space, collaborative areas have been set up (e.g., around the kitchenette), next to video conferencing rooms and booths that ensure staff members are not disturbed as we work together with our teams and clients across different time zones in the US and Europe. Special convenience areas close to work spaces have also been included in the overall design, with future plans of expansions (e.g., purposefully built wellness areas—for now, we are creating a mini-library around the kitchenette space). Lifts and ramps enable disabled access. Free on-site secure parking for employees’ cars and naturally lit bright open plan work areas contribute to the overall aesthetic and functionality of the space. Equipment and optical work benches are segregated to engineering design work desks in order to ensure the areas offer a decluttered space and that engineers can concentrate on focused-centric tasks, if needed.

Q: Given G&H’s ambition to bridge R&D and scalable production, how did the construction timeline and sequencing accommodate validation phases, pilot lines, or early test runs before full-scale operations? Were there any fast-track construction techniques or phased occupancy strategies used?

A: Early on we recognized that getting production to an up-and-running speed, including validation, would represent a critical step on the path to ISO:13485 attainment. To this end, teams of strategists, engineers, and management have been sent over from the UK to work alongside our new US colleagues to put in place the system structure and quality framework for the Innovation Hub. We also included in-house projects to be sent over from the UK to help train personnel and set up a seamless production structure. This factor was key for the development of the Hub R&D and production methodology.

As Dr. Neil Anderson, US sales director for G&H | ITL and General Manager of G&H | GS Optics, mentions, “Through vertical integration and deep application expertise, we help customers move from prototype to production quickly and compliantly” at the new G&H Innovation Hub for Life Sciences, just launched in Rochester, NY.